Getting the right tap and drill bit is easy. Just look up a chart, like this one

http://www.boltdepot.com/fastener-information/us-tap-drill-size.aspx

I only have hands-on experience with the Ideal holders, but I'm sure the Molex are the same. Tightening them down correctly is not a task to be taken lightly. You want the two screws to be even, and just the right amount of force. If you go to the Ideal website

http://www.idealindustries.com/media/pdfs/products/instructions/ND_7868-6_50-21_Instructions.pdf

the instructions say 2.5 - 4.5 inch pounds. That's a tiny amount of force. Small machine screws have fine threads, making it fairly easy to adjust the torque with a small twist of the screwdriver. Self-tappers have large coarse threads, which would be much less effective for adjusting torque.

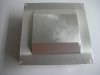

Self-tapping metal screws are designed to be used in an application where you drill completely through the metal and the "drill" part of the screw goes out the other side. A self-tapper wouldn't work in a blind hole, which is probably what you're gonna have if you're drilling into a heatsink.

Just my two cents, but I think self-tappers are a bad idea. As cap'n morgan notes, I'm not at all sure you could find ones that small...

It looks like Ideal has Cree 35XX series holders. They're are a different part # than the 30XX series. The 30XX are part # 50-2234C. The 35XX are 50-2303CR.

http://www.idealindustries.com/products/oem/led_holders/cree.jsp

Oh, whoops, the cap'n already covered that. Sorry..

I agree with Mohican. I'd want a drill press for drilling the holes, but tapping them was easily done by hand. It would have been better with a real tap wrench, but I used a small Vise-Grip instead. And I would definitely use a tapping fluid, like Rapid-Tap.