You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gonna do my first DIY LED with Cree CXA3590

- Thread starter REALSTYLES

- Start date

Abiqua

Well-Known Member

I just ordered my Ideal holders, so I don't have 1st hand experience for them yet, but they call for a M3-04/05 and this is what Real is using, so you would have to drill those out as well, most likely...I just used 6-32 holes instead of the 4-40 for both the 3070s and the 3590s (home depot was out of 4-40's haha). The 3070 holder's holes could be drilled out a tad, but it was easier to do with a larger tap.

But I know what you are saying, 4-40 is damn small, but doesn't help, when a tap not meant for blind holes is also used, like a spiral tip [guilty...]

Abiqua

Well-Known Member

yep...I have seen them as cheap as $50 sometimes...this is my witching hour, still got more to roll....Drill press lol fuck I'm gone

you could also pick up one of these:

http://www.rockler.com/portable-dri...um=cpc&utm_campaign=(roi)+product+listing+ads

REALSTYLES

Well-Known Member

Oh yeah I went to Harbor Freight today and picked up some better bits and a 60 pc Tap and Die Set SAE/METRIC. Plus some Alumiweld rods too see if I can make a frame different from what I'm gonna do. I was born year of the monkey. I have the same birthday as Jimmy Hendrix and Bruce Lee. This last Thanksgiving was my birthday. Don't mind me I'm overly excited. 2015 Year of the COB's lol. I forgot I have some canna butter I;'m making that's been simmering in the crockpot for 24 hours on low. Before then I de-carbonized the material in the oven @ 250F for an hour.

salmonetin

Well-Known Member

Before then I de-carbonized the material in the oven @ 250F for an hour.

...de-carbonized?... ...Decarboxyled... ...Decarboxylation... ...an hour its too much for my POV...

...the curve on the graph (252ºF) decrease at 30 minutes more or less... for my POV ...more time minus terpenoids or minus flavonoids...

http://skunkpharmresearch.com/decarboxylation/

pd... for my POV need a good temp test for the temp oven and controls... better control of temp oven... better results... (PID control, solid state rele, the thermocouple(s)...) ...or an dreamed vacuum oven with better controls...

...its only an opinion...

saludos

Last edited:

Yodaweed

Well-Known Member

Totally right, you should cook butter on the lowest setting for 45 minutes max around 150-250F stirring constantly. If you go too long you will get this nasty burnt weed taste that smells like the weed that comes out of your vaporizer....de-carbonized?... ...Decarboxyled... ...Decarboxylation... ...an hour its too much for my POV...

...the curve on the graph (252ºF) decrease at 30 minutes more or less... for my POV ...more time minus terpenoids or minus flavonoids...

http://skunkpharmresearch.com/decarboxylation/

pd... for my POV need a good temp test for the temp oven and controls... better control of temp oven... better results... (PID control, solid state rele, the thermocouple(s)...) ...or an dreamed vacuum oven with better controls...

...its only an opinion...

saludos

REALSTYLES

Well-Known Member

I read a different article on this and the guy did a test. One batch he cook for 30 minutes had it tested it increased the THC some then he cooked a batch for a hour and had it tested and it produced even higher THC. And I've been doing it and the taste is better and what ever I make like butter or ice cream I can tell the difference....de-carbonized?... ...Decarboxyled... ...Decarboxylation... ...an hour its too much for my POV...

...the curve on the graph (252ºF) decrease at 30 minutes more or less... for my POV ...more time minus terpenoids or minus flavonoids...

http://skunkpharmresearch.com/decarboxylation/

pd... for my POV need a good temp test for the temp oven and controls... better control of temp oven... better results... (PID control, solid state rele, the thermocouple(s)...) ...or an dreamed vacuum oven with better controls...

...its only an opinion...

saludos

REALSTYLES

Well-Known Member

Found the article http://www.marijuanagrowershq.com/decarboxylating-cannabis-turning-thca-into-thc/

see for yourself. The bottom line is everybody has their way of doing things that's what makes us us. I wish you would be able to taste what I make you'd change your mind lol.

see for yourself. The bottom line is everybody has their way of doing things that's what makes us us. I wish you would be able to taste what I make you'd change your mind lol.

REALSTYLES

Well-Known Member

stardustsailor

Well-Known Member

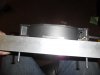

Well here's an update the center COB's are off by a inch but fuck it it's my first DIY light of many to come lol

View attachment 3323055 View attachment 3323056 View attachment 3323057 View attachment 3323058 View attachment 3323059 View attachment 3323060 View attachment 3323061 View attachment 3323062

The 200 mm fan is awesome .

Still ,overall system's cooling efficiency is rather moderate .

(Always in relation with the basic parts used=>large heat sink + large dia. fan )

a ) The four CXAs placed at the very edges of the heatsink ,are "missing" some fin surface over them ,

plus the fact that the air stream from fan,probably would not reach up to there ,to cool the fins.

Solution :Install the chips ,further 'inside' ,towards the center of the heatsink .

b ) The air stream of the fan is not "restricted" within the fin channeling .

Most probably ,the air exiting the fan ,towards heat sink base (fin valleys ) ,

as it has a perpendicular direction to the fin horizon ,will "bounce off " and after some turbulance will be

"exausting " itself ,just nearby the fan.

Solution: Air stream has to be 'restricted' / guided through the fins ,to exaust at the very edges (both ) of heatsink .A lid of some sort has to be installed over the fins ,to form a "duct".Otherwise ,the T differences from being passive ,

would be noticeable only at the center of the heatsink,where fan blows.

Other than that ,it's a great job done .

Cheers.

SupraSPL

Well-Known Member

Those are all good points but in practice, heat management should be very good as is. Because the fan is oversized for the job to reach all the channels, you could drive it at low voltage (5 or 6 V) and still get more than enough air flow. If you were to add fin covers, it would require a higher pressure, so it may not end up more efficient if you had to use a higher voltage.

COB spacing can be tricky. I suspect the most beneficial thing we can do for the plants is try to space the COBs in a pattern gives the most even light spread (staggered) rather than spacing them with an eye toward heat management. That said, those heatsinks have a nice thick base (.3" or 7.62mm) and thick fins, so they should have a relatively low temp gradient no matter where you place them.

COB spacing can be tricky. I suspect the most beneficial thing we can do for the plants is try to space the COBs in a pattern gives the most even light spread (staggered) rather than spacing them with an eye toward heat management. That said, those heatsinks have a nice thick base (.3" or 7.62mm) and thick fins, so they should have a relatively low temp gradient no matter where you place them.

stardustsailor

Well-Known Member

Those are all good points but in practice, heat management should be very good as is. Because the fan is oversized for the job to reach all the channels, you could drive it at low voltage (5 or 6 V) and still get more than enough air flow. If you were to add fin covers, it would require a higher pressure, so it may not end up more efficient if you had to use a higher voltage.

COB spacing can be tricky. I suspect the most beneficial thing we can do for the plants is try to space the COBs in a pattern gives the most even light spread (staggered) rather than spacing them with an eye toward heat management. That said, those heatsinks have a nice thick base (.3" or 7.62mm) and thick fins, so they should have a relatively low temp gradient no matter where you place them.

1) Max power dissipation of pure 20 fan : 2.4 W ..

Even if efficiency sucks ... 2.4 Watts all together ...

2) Heat management comes first ,in order for the cobs to operate as efficiently as possible ,no matter the Io* .

A good cooled COB will operate at higher driving currents ,with same or even higher rad. efficiency ,

than a moderately cooled COB ,driven at lower current than the first one.

Light spread comes second regarding designing ,as instead of a huge long heatsink ,3x smaller ones could have been used in place ,each bearing two chips on it( and with it's own fan

Or appropriate optics can be installed ,also ,to manage light spread.

Light spread issues can be solved by several / few alternatives.

Cooling issues definately share not the same possibility.

3) Nice thick base of .312" ,24" long ,1.312 high ,7" wide ....

As I said ...Even when 130 cfm of air (pure 20 ) are impinged ALL OVER the fin surface area ..

( A LID IS THEORETICALLY USED ) ..

Still the heatsink is too long ...

The 200 mm fan ,at max and with a lid on ,still will have trouble evenly cooling those cobs ..

But,that is merely ,only my opininion.

Some real life testing ,with a thermocouple attached to the appropriate Tc points of cobs ,

can reveal more closely to the truth ,what actually is going on .

I'm really hoping to be proved wrong about my assumptions ,on this topic .

Cheers.

Last edited:

stardustsailor

Well-Known Member

Heat management ,( especially in a D.I.Y. design where the maker seldom has the ability to 'test' the cooling

efficiency of the design with the use of a thermal camera or advanced computational fluid dynamics software -CFD ),

is a rather complicated issue and is not so simple as "take a large heatsink & a large fan ,place the cobs as apart as possible and there you're ,you 've made yourself a LED growing light " ..

Base thickness is directly related to the surface of the heat source in contact with the heat sink .

The smaller the surface of the heat source ,the thicker the base has to be .

In order to spread heat ,as evenly and as "far" from the source- as heat conducts towards the fins .

The longer the " flow length " ( the distance air stream has to cover ,before exiting the fins ) ,

the wider the fin spacing has to be .Wide thin spacing ,means thin fins ,instead of thick ones ...

Otherwise the number of fins should decrease .Not good .

(...) Conclusion

In summary, the optimum fin spacing for a fan-cooled heat sink was found to be primarily a

function of flow length. With a 50 CFM/25 Pa fan, the optimum spacing was 2.0 mm at L flow = 75 mm,

2.8 mm at L flow = 150 mm and 4.0 mm at L flow = 300 mm. With a higher capacity fan,

the optimum fin spacing will decrease, but not dramatically. Similarly, the use of a lower

capacity fan will increase the optimum fin spacing by a moderate amount. Designers need to

be aware that the use of a fin spacing which is less than the optimal value can result in very

poor heat sink performance.

When the base-to-tip fin length was modified, there was virtually no impact on the optimum fin

spacing. It was observed that there are diminishing benefits for fin lengths greater than 50 mm,

although this will impacted by fan capacity.

Finally, it should be remembered that all optimizations were for steady state conditions with a

uniform backplane temperature. For point source heat loading, there will be some impact on

optimum dimensions, although it is expected that the impact will generally be slight. For

transient and duty cycle operation, there will be a shift toward fin spacings which increase the

overall heat sink mass. (...)

http://www.thermalsoftware.com/optimum_sink_fan.pdf

(...) Flow length variation

Since the fin height, number and thickness

now is constrained by manufacturability, it is worth

checking whether the flow length has any effect. It is

possible, as the upper curve in Figure 6 shows, that

an increase in the flow length (and thus fin area)

could paradoxically increase the thermal resistance.

This performance degradation is caused by the higher

pressure drop of the longer flow length and the flow

delivery characteristic of the fan.(...)

http://biberthermal.com/Reference_Links/Publications_List/isps99paper.pdf

Edit: Needless to mention that the fans (pure20) have to operate at max power .

But even then ....24" is too long ...

65 CFM for 12" ( fan on top ,impinge = 130 CFM /2 , flow length = 24"/2 ) ..

And without "guidance" across the fins ?

.....

I've already expressed my concerns ..

Cheers.

efficiency of the design with the use of a thermal camera or advanced computational fluid dynamics software -CFD ),

is a rather complicated issue and is not so simple as "take a large heatsink & a large fan ,place the cobs as apart as possible and there you're ,you 've made yourself a LED growing light " ..

Base thickness is directly related to the surface of the heat source in contact with the heat sink .

The smaller the surface of the heat source ,the thicker the base has to be .

In order to spread heat ,as evenly and as "far" from the source- as heat conducts towards the fins .

The longer the " flow length " ( the distance air stream has to cover ,before exiting the fins ) ,

the wider the fin spacing has to be .Wide thin spacing ,means thin fins ,instead of thick ones ...

Otherwise the number of fins should decrease .Not good .

(...) Conclusion

In summary, the optimum fin spacing for a fan-cooled heat sink was found to be primarily a

function of flow length. With a 50 CFM/25 Pa fan, the optimum spacing was 2.0 mm at L flow = 75 mm,

2.8 mm at L flow = 150 mm and 4.0 mm at L flow = 300 mm. With a higher capacity fan,

the optimum fin spacing will decrease, but not dramatically. Similarly, the use of a lower

capacity fan will increase the optimum fin spacing by a moderate amount. Designers need to

be aware that the use of a fin spacing which is less than the optimal value can result in very

poor heat sink performance.

When the base-to-tip fin length was modified, there was virtually no impact on the optimum fin

spacing. It was observed that there are diminishing benefits for fin lengths greater than 50 mm,

although this will impacted by fan capacity.

Finally, it should be remembered that all optimizations were for steady state conditions with a

uniform backplane temperature. For point source heat loading, there will be some impact on

optimum dimensions, although it is expected that the impact will generally be slight. For

transient and duty cycle operation, there will be a shift toward fin spacings which increase the

overall heat sink mass. (...)

http://www.thermalsoftware.com/optimum_sink_fan.pdf

(...) Flow length variation

Since the fin height, number and thickness

now is constrained by manufacturability, it is worth

checking whether the flow length has any effect. It is

possible, as the upper curve in Figure 6 shows, that

an increase in the flow length (and thus fin area)

could paradoxically increase the thermal resistance.

This performance degradation is caused by the higher

pressure drop of the longer flow length and the flow

delivery characteristic of the fan.(...)

http://biberthermal.com/Reference_Links/Publications_List/isps99paper.pdf

Edit: Needless to mention that the fans (pure20) have to operate at max power .

But even then ....24" is too long ...

65 CFM for 12" ( fan on top ,impinge = 130 CFM /2 , flow length = 24"/2 ) ..

And without "guidance" across the fins ?

.....

I've already expressed my concerns ..

Cheers.

Last edited:

Dloomis514

Well-Known Member

I might have placed on set of cobs in the middle of the fixture and the other 1/2 the way between there and the edge, not on the edge. The heatsink will dissipate the heat better that way.Well here's an update the center COB's are off by a inch but fuck it it's my first DIY light of many to come lol

View attachment 3323055 View attachment 3323056 View attachment 3323057 View attachment 3323058 View attachment 3323059 View attachment 3323060 View attachment 3323061 View attachment 3323062

stardustsailor

Well-Known Member

stardustsailor

Well-Known Member

SupraSPL

Well-Known Member

SDS, a small power wastage in the cooling system can take a decent sized chunk out of the efficiency of the system (moreso in a CPU cooler situation). But a slightly higher Tj does not affect light output as much. I have tested this myself and I was shocked by the results. The effect is most noticeable in CPU coolers like the Alpine 11 because the cooling power is overkill and therefore inefficiently used, but it would apply to this setup as well to some extent. This setup is using its cooling power much more efficiently because a single fan is cooling 6 COBs rather than 6 fans in the Alpine11 example.

Yes I would have staggered them as you have shown to get even cooling, but most importantly to get as even light spread in the canopy as possible.

Even at 5-6V that fan may be adequate to cool the system. The air will stay in the channels with no problem and blow out the ends. I have tested this on a 24"X5.88" heatsinks. I suspect, if we ran that fan higher than 5 or 6V, we may actually lose efficiency overall but I would love to test it. It is true that as we increase the air flow, temp gradient is reduced and Tj is slightly cooler, but temp droop would barely be affected whether we ran it at 5V or 9V or 12V.

Yes I would have staggered them as you have shown to get even cooling, but most importantly to get as even light spread in the canopy as possible.

Even at 5-6V that fan may be adequate to cool the system. The air will stay in the channels with no problem and blow out the ends. I have tested this on a 24"X5.88" heatsinks. I suspect, if we ran that fan higher than 5 or 6V, we may actually lose efficiency overall but I would love to test it. It is true that as we increase the air flow, temp gradient is reduced and Tj is slightly cooler, but temp droop would barely be affected whether we ran it at 5V or 9V or 12V.

Last edited:

REALSTYLES

Well-Known Member

Thank you for your input and the air does go through every fin in both directions and the sized of the heat sink should be ok I hope lol. Like I said this is my first DIY led.The 200 mm fan is awesome .

Still ,overall system's cooling efficiency is rather moderate .

(Always in relation with the basic parts used=>large heat sink + large dia. fan )

a ) The four CXAs placed at the very edges of the heatsink ,are "missing" some fin surface over them ,

plus the fact that the air stream from fan,probably would not reach up to there ,to cool the fins.

Solution :Install the chips ,further 'inside' ,towards the center of the heatsink .

b ) The air stream of the fan is not "restricted" within the fin channeling .

Most probably ,the air exiting the fan ,towards heat sink base (fin valleys ) ,

as it has a perpendicular direction to the fin horizon ,will "bounce off " and after some turbulance will be

"exausting " itself ,just nearby the fan.

Solution: Air stream has to be 'restricted' / guided through the fins ,to exaust at the very edges (both ) of heatsink .A lid of some sort has to be installed over the fins ,to form a "duct".Otherwise ,the T differences from being passive ,

would be noticeable only at the center of the heatsink,where fan blows.

Other than that ,it's a great job done .

Cheers.

REALSTYLES

Well-Known Member

1) Max power dissipation of pure 20 fan : 2.4 W ..

Even if efficiency sucks ... 2.4 Watts all together ...

2) Heat management comes first ,in order for the cobs to operate as efficiently as possible ,no matter the Io* .

A good cooled COB will operate at higher driving currents ,with same or even higher rad. efficiency ,

than a moderately cooled COB ,driven at lower current than the first one.

Light spread comes second regarding designing ,as instead of a huge long heatsink ,3x smaller ones could have been used in place ,each bearing two chips on it( and with it's own fan..).

Or appropriate optics can be installed ,also ,to manage light spread.

Light spread issues can be solved by several / few alternatives.

Cooling issues definately share not the same possibility.

3) Nice thick base of .312" ,24" long ,1.312 high ,7" wide ....

View attachment 3323664

View attachment 3323665

As I said ...Even when 130 cfm of air (pure 20 ) are impinged ALL OVER the fin surface area ..

( A LID IS THEORETICALLY USED ) ..

Still the heatsink is too long ...

The 200 mm fan ,at max and with a lid on ,still will have trouble evenly cooling those cobs ..

But,that is merely ,only my opininion.

Some real life testing ,with a thermocouple attached to the appropriate Tc points of cobs ,

can reveal more closely to the truth ,what actually is going on .

I'm really hoping to be proved wrong about my assumptions ,on this topic .

Cheers.

Is that a simulation or actually testing?

Similar threads

- Replies

- 3

- Views

- 387

- Replies

- 8

- Views

- 624

- Replies

- 4

- Views

- 438

- Replies

- 9

- Views

- 641