http://www.ledsmagazine.com/ugc/201...engths-to-set-a-new-industry-standard-fo.html

Hubbell Lighting improves NutriLED horticultural LED luminaire with more wavelengths

Published on:July 4, 2016

Introduced as a breakthrough in horticultural technology in early 2015, NutriLED was one of the first to use LED technology to provide light for plant growth and development in indoor horticulture applications. The technology has evolved to establish the industry standard for those who are converting high-pressure sodium (HPS), metal halide and fluorescent lighting in their operations to more efficient LED sources.

What's New?

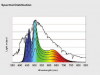

Originally the NutriLED was offered to customers with a blend of red and blue wavelengths and light intensities that were ideal for vegetative growth but not flexible enough for flowering growth. The research team at Hubbell Lighting has developed an updated version of the NutriLED product that increases the level of light intensity for high light plants and adds far-red wavelength to improve productivity. The "Flowering Spectral Mix" diagram below shows how the far-red wavelength has increased.

In one pilot study featuring this new version of the NutriLED, a customer has benefited from flowering beginning a full two weeks earlier than normal, a 25 percent increase in the yield and a bigger flowering bud.

"When we originally developed NutriLED, our goal was to provide a high performance horticultural fixture that would improve and enhance indoor, greenhouse and vertical farming," said Dr. Yan Ren-Butcher, horticultural staff scientist and Hubbell Lighting's resident expert in the field of indoor and greenhouse farming. "Having achieved that goal, we began investigating how we could improve the product further with the end customer in mind. The new flowering mix can enhance flowering in a variety of species and provides flexible options for customers who need higher light intensity."

NutriLED customers have responded favorably to the expertise of Dr. Ren-Butcher and her ability to design lighting layouts specific to their operations in regards to light intensity. For example, Dr. Jeffrey Adelberg, Professor of Horticulture at Clemson University, called on Dr. Ren-Butcher to assist in the design of lighting layouts for his microgreen research to identify optimal light intensity.

The vertical farming industry in particular is one that has undergone significant growth over the last year. It's no secret that the advent and deployment of new technologies like LEDs have had an influential role in this trend. While the idea of using LEDs to grow plants isn't new, NASA was investigating it back in the 1980s, the technology has improved, the production price has decreased and studies show that results with LEDs are equivalent to traditional light sources.

The advantage of NutriLED is the 64 percent energy savings over traditional non-LED grow lights, increased maintenance savings and a significant drop in waste. For example, as a direct result of significantly reducing the radiant heat produced by conventional lighting technology, water usage can also be reduced, and the need for supplemental HVAC cooling loads may be completely eliminated in some applications.

Additional Features and Benefits of the NutriLED:

• Extruded aluminum housing

• UV stable clear acrylic lens

• Sealed power connectors in each end

• Three industry standard TEE slots for mounting options

• Parabolic reflector for precise light distribution

• 120v through 277v AC

• Unit is qualified for operation in a 50°C (122°F) ambient environment

• Damp location standard; Wet location optional

• Five year warranty