I do enjoy these debates

Now the antithesis of the "pie chart" chart law is the inverse-square law. It simply states that every time you double the distance of a light source, you halve the energy through spherical dispersion. So with a single light source, the edges and corners of a square trellis get the least amount of light, as it geometrically must travel further to get there.

View attachment 4008537

For a single light source, a sphere is the most efficient trellis dimension, as equal light is distributed across all surface areas. With a HPS bulb - which is cylindrical - a tube is the most efficient shape.

I know that vertical trellis growers such as ttystikk use multiple light sources, but I'm just explaining the theory - which you guys probably already know

In practice, vertical grows are not very dense - and they are very much a scrog. While the buds do get thicker, and they do move towards the light creating a "pie wedge" effect, they mostly grow up along the cylindrical trellis and as buds form, the grower (me in this case) weaves the branches horizontally and vertically into the trellis to fill in any gaps. The plants themselves end up being somewhat of a fan shape, spread out and around the trellis (I actually call it a "cage") as in the photo below. (One of the buds has been pulled to one side to show the position of the 600w HPS bulb. There is another 600w bulb down the bottom, in the middle of all that tangle.)

View attachment 4008540

The plants themselves look like this - tall, sticky branches that are somewhat fanned out (bunched together a little bit in this photo to stop the branches falling off to the sides and snapping under their own weight):

View attachment 4008541

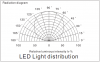

The interesting thing about LED light dispersion is that many of you have seen these charts:

View attachment 4008544

This one is typical of a 120-degree angle LED light source. It's also a bit misleading, as there is ALWAYS ambient light that falls outside the ranges provided. Here is a more accurate depiction of LED light distribution. Remember, these are only examples to highlight my point - I'm not arguing the merits of individual LEDs:

View attachment 4008545

So what happens to all that light that emits between the 180 degree plane of the light source (the perfect horizontal) and the canopy, which at the most (depending on how close you can get your lights to the canopy) falls within that 120-degree angle? Even in the first diagram you can see a lot of strong light falling outside the 150-degree and 30-degree planes (representing the limit of the 120-degree splay).

What else is interesting is, notice how the light intensity is curved, almost like a perfect circle? This also demonstrates what I mean about the sphere or cylinder being the most efficient shape for a single light source, as light intensity is spread equally around the circle.

This all seems obvious with a HPS bulb that emits in 360-degrees. But what I have shown above leads me to believe there are efficiencies to be gained with vertical LED in a cylindrical or hexagonal shape. A cylinder would probably be best, but a hexagon would be a good compromise with 120-degree LEDs, as the diameter of the plants would likely coincide with where the 120-degee beam angles converge on each of the six sides.

I also believe 120-degree LEDs have less refractive losses - and are more efficient - than narrower-angle LEDs, making them an ideal choice.

I like the idea of a flat trellis vertical grow to make use of head height - the results speak for themselves. But respectfully, it is for the most part a horizontal grow turned on its side with the same geometry. And while a cylindrical grow could be seen as compromising a square footprint, remember, you need to access your plants if you are going to scrog them. A cylinder allows access from all sides.

Of course, this is all hypothetical on my part in relation to LEDs as I have not done it yet.