So I think these $100+ commercial cycle timers are way overkill for a small-time grower like me. Or the price is overkill, at least. I have come across a mechanical timer sort of like those cheap light timers you see at walmart, except you can set it to turn on/off in 50 second increments. That probably would have been good enough for my system, and cheaper than what I am about to propose, but I am an electronics hobbyist with lots of spare parts laying around, and this was the perfect excuse to start a new project.

I saw another timer that someone else had posted, here. It seems very nice in it's own right, and I didn't want to steal this guy's thunder by posting in that thread. My timer is far less sophisticated, but it gets the job done with very few parts, so if you are handy with a soldering iron it is easy to assemble and as you are about to see, it can fit in a small space.

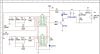

Here is the schematic:

The key component here is the 5555 programmable delay timer (U1 and U2). As the name suggests, part of it operates similarly to the 555 timer, in that you use a resistor and capacitor in series to control the oscillator frequency. But a 555 timer is only useful up to maybe a few seconds; way less than a typical nutrient pump cycle. The 5555 is far more accurate at timing longer periods of time because the oscillator output is fed into an integrated pulse counting circuit. When triggered, it turns on the output, and after a certain number of pulses elapse, it turns off the output. What makes it even better for timing applications is the ability to select how many stages the pulse counter uses, allowing you to control how many pulses get counted before triggering the output. The counting stages are selected by connecting the S0-S3 pins to ground or VCC. I left these pins open on the schematic, but if you want to build this, you need to tie these high or low, depending on your timing needs. This part can trigger the output after a delay of milliseconds or days, and anywhere in between.

Here is a rough theory of operation:

I am using two of these 5555 timers, allowing independent control of on/off time (U2 controls the ON time, and U1 controls the OFF time). The 5555 will not start counting pulses until it is triggered (either by the "A" pin going from low to high, or the "/B" pin going from high to low). This trigger needs to occur after power is applied, so to set things in motion I am using a capacitor (C2) on the "A" pin of U1. When power is applied, this cap gets charged through R7, so the voltage on the "A" pin slowly rises and triggers the timer at some point after power-on (this happens in a fraction of a second, so it is unnoticeable).

Each timer has complimentary output pins "Q" and "/Q", so when one is on, the other is off, and vice versa. So on power-up, U2 is triggered, and the Q output pin of U2 goes high, turning on the transistor Q1, which allows current to flow through the relay control. The complimentary output pin "/Q" is connected to the "A" trigger input of the OFF timer (U1), but at this point the output of /Q is low. During this time, the Q output of U1 is pulled low, which means current is flowing through the LED, indicating that the circuit is in the "ON" part of the cycle. After U2 has counted the selected number of pulses, it turns the output "Q" off, (which turns the relay off), and /Q goes high. This triggers U1, so this timer turns it's Q output on (which turns the LED off), and begins counting it's pulses. You will notice the Q output of U1 is connected to the /B trigger of U2. When U1 is done counting it's pulses, it turns Q off, which triggers U2 to turn it's Q output on (turning the relay back on) and starting the cycle over again. This repeats indefinitely until you disconnect power.

Some notes about the design:

For assembly, I soldered the through hole components onto a small piece of perf board. To save space, I chose surface mount components for the resistors and caps and soldered them along with all of the interconnects on the bottom side. I made 3 exact copies of the circuit, so I have 3 independently timed relays that are able to switch AC power to individual outlets. To power the circuit, I found a very tiny AC/DC power supply here: www.allelectronics.com

I went to lowes and got some bulk power cord, AC outlets, and a 4" x 4" 'handy box'. These boxes are compact and made from very rugged stamped metal, and best of all they only cost a couple of bucks. Perfect for this application. But would everything fit???

Indeed it does! The power supply and perf board are bolted to the bottom of the box. There is a piece of lexan lining the bottom to prevent electrical shorts. 3 of the outlets are connected to their own relay, and the 4th outlet connected straight to power, so it is always on...

So that's it! I have been running this thing non-stop for about 2 months now. The pump cycle timing has remained accurate, and my plant is very happy. Aside from the 1minute/5minute pump cycle, I have another outlet set for 12hours on/12hours off and the third one set for 18h/6h for lighting control... This works okay for a little bit, but after long periods of time it begins to lose sync, since the cycle is not exactly 24 hours. If I build another one of these, it will have a smaller AC/DC power supply, and a 24 hour reset circuit for precise lighting control.

Hope this helps somebody!

I saw another timer that someone else had posted, here. It seems very nice in it's own right, and I didn't want to steal this guy's thunder by posting in that thread. My timer is far less sophisticated, but it gets the job done with very few parts, so if you are handy with a soldering iron it is easy to assemble and as you are about to see, it can fit in a small space.

Here is the schematic:

The key component here is the 5555 programmable delay timer (U1 and U2). As the name suggests, part of it operates similarly to the 555 timer, in that you use a resistor and capacitor in series to control the oscillator frequency. But a 555 timer is only useful up to maybe a few seconds; way less than a typical nutrient pump cycle. The 5555 is far more accurate at timing longer periods of time because the oscillator output is fed into an integrated pulse counting circuit. When triggered, it turns on the output, and after a certain number of pulses elapse, it turns off the output. What makes it even better for timing applications is the ability to select how many stages the pulse counter uses, allowing you to control how many pulses get counted before triggering the output. The counting stages are selected by connecting the S0-S3 pins to ground or VCC. I left these pins open on the schematic, but if you want to build this, you need to tie these high or low, depending on your timing needs. This part can trigger the output after a delay of milliseconds or days, and anywhere in between.

Here is a rough theory of operation:

I am using two of these 5555 timers, allowing independent control of on/off time (U2 controls the ON time, and U1 controls the OFF time). The 5555 will not start counting pulses until it is triggered (either by the "A" pin going from low to high, or the "/B" pin going from high to low). This trigger needs to occur after power is applied, so to set things in motion I am using a capacitor (C2) on the "A" pin of U1. When power is applied, this cap gets charged through R7, so the voltage on the "A" pin slowly rises and triggers the timer at some point after power-on (this happens in a fraction of a second, so it is unnoticeable).

Each timer has complimentary output pins "Q" and "/Q", so when one is on, the other is off, and vice versa. So on power-up, U2 is triggered, and the Q output pin of U2 goes high, turning on the transistor Q1, which allows current to flow through the relay control. The complimentary output pin "/Q" is connected to the "A" trigger input of the OFF timer (U1), but at this point the output of /Q is low. During this time, the Q output of U1 is pulled low, which means current is flowing through the LED, indicating that the circuit is in the "ON" part of the cycle. After U2 has counted the selected number of pulses, it turns the output "Q" off, (which turns the relay off), and /Q goes high. This triggers U1, so this timer turns it's Q output on (which turns the LED off), and begins counting it's pulses. You will notice the Q output of U1 is connected to the /B trigger of U2. When U1 is done counting it's pulses, it turns Q off, which triggers U2 to turn it's Q output on (turning the relay back on) and starting the cycle over again. This repeats indefinitely until you disconnect power.

Some notes about the design:

- Timing... well I'll admit, this circuit is not user friendly for people who don't like fucking around with these things, but once you get things set the way you want, adjusting the time is fairly simple...The ON and OFF times are roughly controlled by the stage selection of the 5555's, and then I select an appropriate timing resistor/capacitor combination to get closer to the time I want (on the schematic, this is R2/C4 for U2 and R8/C7 for U1)... Lastly, I fine-tune the time delay with a potentiometer. For example, if I want a 1 minute on/5 minute off cycle, a proper stage selection and RC combination would get me to ~40 seconds on/3.5 minutes off if the potentiometers are set to the lowest point. If I turn the potentiometers all the way up, it might be 1.5 minutes on, 6 minutes off. So the idea is to find the correct "window" of time, and then adjust to the exact time that you want with the potentiometers. Once it's set you don't have to touch it again.

- The relay K1 is shown as a mechanical relay. On my actual circuit, I am using a fairly inexpensive solid state relay, the Sharp S101S05F. I consider this a major advantage, since it is far more reliable than a mechanical relay, especially for inductive loads (i.e. your nutrient pumps, air pumps, fans, what have you). For an application that requires switching hundreds of times every day (such as a nutrient pump), these SSRs should last years instead of months. However since the 5555 output is buffered by the transistor Q1, it should be able to handle any type of relay as long as it operates on 5VDC. In any case, you should also include a snubber circuit across the relay output (C5 and R6).

For assembly, I soldered the through hole components onto a small piece of perf board. To save space, I chose surface mount components for the resistors and caps and soldered them along with all of the interconnects on the bottom side. I made 3 exact copies of the circuit, so I have 3 independently timed relays that are able to switch AC power to individual outlets. To power the circuit, I found a very tiny AC/DC power supply here: www.allelectronics.com

I went to lowes and got some bulk power cord, AC outlets, and a 4" x 4" 'handy box'. These boxes are compact and made from very rugged stamped metal, and best of all they only cost a couple of bucks. Perfect for this application. But would everything fit???

Indeed it does! The power supply and perf board are bolted to the bottom of the box. There is a piece of lexan lining the bottom to prevent electrical shorts. 3 of the outlets are connected to their own relay, and the 4th outlet connected straight to power, so it is always on...

So that's it! I have been running this thing non-stop for about 2 months now. The pump cycle timing has remained accurate, and my plant is very happy. Aside from the 1minute/5minute pump cycle, I have another outlet set for 12hours on/12hours off and the third one set for 18h/6h for lighting control... This works okay for a little bit, but after long periods of time it begins to lose sync, since the cycle is not exactly 24 hours. If I build another one of these, it will have a smaller AC/DC power supply, and a 24 hour reset circuit for precise lighting control.

Hope this helps somebody!