Still unsure, but it's very possible

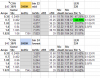

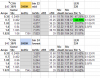

I found the COBs for 33$ a piece in multiples of 20, so that's tempting. Just to confirm the estimated efficiency for the 3K 3070 is about 47, 42, and 39 % at .35, .7, and 1.05 respectively?

Yessr here are the updated numbers. The original numbers were estimated from the PDF but for the more accurate numbers I counted the pixels in MSpaint.

I know you mentioned the KNNA values of 20% for blue during flower as potentially idea. This is important to me as I plan no other supplemental lighting aside from the 3070... Looking at the umols/s/nm for these emitters posted in the cre cxa analysis thread (thank you Flux) it would appear that I need a way to calculate the area under the curve. I believe I read that you mentioned the 3K has about 10% blue. How did you calculate this? I am attempting to calculate the 3K:5K (or even 3K:4K:5K) ratio I need to arrive at to fulfill the spectral requirements through veg and bloom based on the photosynthesis charts I have compiled.

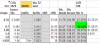

Thankfully KNNA specified PAR WATTS when he have us the 15-20% number. When I mentioned 10% for the 3000K CCA3070 I got that number from Mr Flux's data:

CXA 3000K

Blue : 10% power, 8% flux

Red : 24% power, 27% flux

CXA 4000K

Blue : 19% power, 16% flux

Red : 17% power, 20% flux

CXA 5000K

Blue : 24% power, 20% flux

Red : 14% power, 17% flux

I have also used the counting boxes method for the 3000K XTEs and I arrived at 11% (different phosphor). For vegging the 4000K or 5000K could be very helpful. Unfortunately the 5000K from Digikey is the lowest bin. Where did you find them for $33?

Also, how is your build going? I agree that lapping is difficult given the size of these sinks and is probably unnecessary with the thermal mass / area you are using per watt. Were you lapping with the 3M paper tapped to a piece of glass? Also, I believe you mentioned polishing. I typically forgo this step, as it is my belief that these buffing compounds leave a residue that may actually impede thermal conductivity vs the freshly lapped surface itself.

Cheers!

Got all the wiring from elecdirect but still waiting on the drivers so I have been working on another pair of driver boards for 300W each. Last time I used 1/2" plywood and but it is much heavier than necessary. Home Depot was out of pegboard so I am using a 1/4" sheet of underlayment and it is much better. I just drilled holes and will zip the drivers to the board. Made some power terminals and zipped those on.

To polish the big sinks I start off with 80 grit on a palm sander. That does the majority of the work. Then I go to 220 until all the 80 grit scratches are out. Finally 600 with a 3M manual sanding block. When I was polishing them I would continue to 1000 1500 and 2000. Then I would use a pair of liquid compounds and finally aluminum polish. I decided that none of that was necessary and 600 grit should be a good value point. I agree that the aluminum polish leaves a residue. I was using alcohol to try and dissolve it afterward.

I also go to 600 grit on all of my aluminum stars. Every single one of them is a far cry from flat lol.