SupraSPL

Well-Known Member

I have been avoiding this issue and focusing on efficiency for starters. We have that pretty well sorted out along with heatsinks, so now I am wondering how we can maximize our yield with reflectors. This is going to become important as we (hopefully) start to see commercial lamps cranking lots of juice through Vero 29s. It is also important for those who are running that CXA3070 at 1.4A or higher.

If you have a CXA COB holder or a Vero, there are really nice aluminum reflectors that you can attach to the holders.

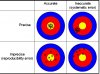

But these can add significant cost to large builds and availability of reflectors for the large COBs seems to be a problem. So for now, I am looking into makeshift reflectors. First thing is first, what kind of paint or surface is the most efficient? I cut holes in a bunch of yogurt cups and painted them with flat white, satin white, gloss white and chrome (Rustoleum brand paints). The angle of the yogurt cups is probably too steep for what we need, but since they are all the exact same size it will allow us to see what surfaces perform best. I will experiment with different shapes later on.

First test, Vero29 driven at 1.5A, cold pulse measurements from 15" away, directly on center

No reflector: 149 (100%)

Plain white plastic: 186 (125%)

Satin white (2 layers): 189 (127%)

Gloss white (2 layers): 189 (127%)

Chrome(2 layers): 178 (119%)

Flat white (1 layer): 201 (135%)

Flat white (2 layers): 206 (138%)

Flat white (3 layers): 206 (138%)

Flat white (2 layers, Walmart brand): 198 (133%)

Aluminum foil sloppy wrap job: 238 (160%)

Next I measure 8" off to the side. It was very interesting to see that a thicker layer of flat white actually improved reflection significantly. The sloppy foil wrap was a real surprise but will have to see how it performs off-angle.

If you have a CXA COB holder or a Vero, there are really nice aluminum reflectors that you can attach to the holders.

But these can add significant cost to large builds and availability of reflectors for the large COBs seems to be a problem. So for now, I am looking into makeshift reflectors. First thing is first, what kind of paint or surface is the most efficient? I cut holes in a bunch of yogurt cups and painted them with flat white, satin white, gloss white and chrome (Rustoleum brand paints). The angle of the yogurt cups is probably too steep for what we need, but since they are all the exact same size it will allow us to see what surfaces perform best. I will experiment with different shapes later on.

First test, Vero29 driven at 1.5A, cold pulse measurements from 15" away, directly on center

No reflector: 149 (100%)

Plain white plastic: 186 (125%)

Satin white (2 layers): 189 (127%)

Gloss white (2 layers): 189 (127%)

Chrome(2 layers): 178 (119%)

Flat white (1 layer): 201 (135%)

Flat white (2 layers): 206 (138%)

Flat white (3 layers): 206 (138%)

Flat white (2 layers, Walmart brand): 198 (133%)

Aluminum foil sloppy wrap job: 238 (160%)

Next I measure 8" off to the side. It was very interesting to see that a thicker layer of flat white actually improved reflection significantly. The sloppy foil wrap was a real surprise but will have to see how it performs off-angle.

Last edited:

.

.