Yet More Street Lamps and started VLR#3

I was at the scrap yard this morning returning the carcasses of the two 50 watt lamps I picked up on Friday, when the guy said there were another two 100 watt lamps. So, I told him to hang onto the $10 deposit and I'd bring these back stripped in a couple of days, cause there might be more arriving by then and since I can get the components and other parts for free, why not. On one lamp I took off the driver cover and lenses and made sure there was noting obvious or dangerous, then hooked it up to 120 for a quick test. One complete side was out, which was strange since it was wired so that if one side of the driver failed, it would shut either the front or rear array down in each panel, not a complete side! Anyway I switched it off and jiggled the wiring harness for the bad side and plugged it in again, worked perfect and it looks like it was never even installed, 0 hours , go figure. I'll have a look at the other lamp tomorrow and keep my fingers crossed. Out of 15 scrap street lights, 3 were working so far and 2 out of the 3 were never installed, and I haven't tested most of the other drivers yet.

Check your local scrap yard and find out where the local utility scrap goes. These lights are a pain to most scrap dealers and the only thing of value in these lamps to them is the aluminum (about 16 lbs of it) and stripping off the plastic lenses, arrays and drivers as well as other parts is a problem and time consuming. That's why they would most likely allow you to put a deposit on the lamps and strip them for him, it's a classic win, win situation, he gets the cleaned aluminum casting plus a few other aluminum parts, you keep the rest, for the cost of your labor. Out of every thousand new lamps there will be a few failures and many communities will have tens of thousands of street lamps that are in the process of being converted from HID. If it works like around here, the failure rate for these lamps is so low that they don't even have a provision made to return or repair them.

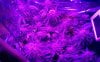

VLR#3 Progress

Got the cooling tubes mounted to the support frame (aluminum angle this time) and all squared up for VLR#3. Next I'll drill holes for grommets, mount the arrays, cover them with masking tape and do the rough wiring. Then I'll flip it over to mount the electrical box, the driver, the fan power supply and the terminal block. I'm going to use a salvaged ATX computer power supply with 2 fans for the electrical box on this one, all I have to do is cut a hole in to bottom of the box. I wish I had thought of this instead of monkeying with that cheap dollar store cookie box, would have been much easier and quicker with the fans, computer power cord connector and the switch already taken care of.