robincnn

Well-Known Member

Wanted to start a new thread for my passive heatsinks. I will be sharing updates and some test results in this thread.

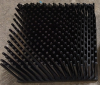

Please feel free to talk about Pin heatsinks

So what makes PIN Heatsinks better ?

http://www.newelectronics.co.uk/ele...oint-the-way-to-more-efficient-cooling/18641/

https://www.linkedin.com/pulse/2014...-use-pin-fin-heat-sink-for-led-lighting-today

PIN passive heatsinks are more efficient at cooling so this means they can cooler better and weight less.

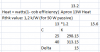

I have been testing these since late last year. Most of my testing was with a 100W power resistor. GG recently shared some test results in his thread.

I wanted to compare how these Pin heatsinks perform vs flat heatsinks.

Please feel free to talk about Pin heatsinks

So what makes PIN Heatsinks better ?

http://www.newelectronics.co.uk/ele...oint-the-way-to-more-efficient-cooling/18641/

To explain how pin fin heat sinks achieve more efficient cooling, it's helpful to briefly discuss the elements that determine the cooling capability of any heat sink: surface area; metallurgy; and the impact of heat sink structure on incoming airstreams.

Many designers recognize the importance of the first two elements – greater surface area and more thermally conductive materials tend to make heat sinks more efficient. But fewer engineers understand the significance of the last element – how the heat sink structure uses surrounding air streams. And it's this aspect of heat sink design that has the greatest effect on performance.

While early devices consisted mainly of sheet metal components and simple bidirectional aluminum extrusions, heat sinks have evolved into omnidirectional, often exotic, constructions. But, in terms of performance, the most important advances relate to structural changes that enable heat sinks to make the best use of surrounding airflows.

The popularity of pin fin heat sinks is growing, thanks to their exceptional cooling capabilities, which stem from their round pin geometry, omnidirectional configuration and use of highly conductive materials. The round, aerodynamic pin design reduces resistance to surrounding airstreams that enter the pin array, while simultaneously increasing air turbulence. The omnidirectional pin configuration, which allows air to enter and exit the heat sink in any direction, exposes the heat sink to the fastest possible air speed. That fast airflow in and out of the heat sink in combination with the large surface area of the pin fin heat sink, results in very efficient heat removal.

https://www.linkedin.com/pulse/2014...-use-pin-fin-heat-sink-for-led-lighting-today

Generally, a heat sink should work better when it has a large surface area, but this is not true in all the cases. The pin fin heat sink works on the concept of packing as much surface area as possible into any particular volume. One can also find straight fin heat sinks, but Pin Fin heat sinks work better than them as the fluid flows along the pins axially instead of flowing tangentially.

PIN passive heatsinks are more efficient at cooling so this means they can cooler better and weight less.

I have been testing these since late last year. Most of my testing was with a 100W power resistor. GG recently shared some test results in his thread.

I wanted to compare how these Pin heatsinks perform vs flat heatsinks.

Last edited: