sixstring2112

Well-Known Member

yeah man even if those temp probes are off by 10% which i bet they are not,you still showed the pins being cooler by enough to make a serious case for pin fin.awesome video as usual gm.

I think it's certainly convincing in terms of reasonable standards. Research projects attempt to create datasets and draw all but unassailable results, I don't think that standard is necessary here, nor will more rigorous methods yield substantially different results.Thanks Robin.

-36" L 5.886 HSusa profile: 9lbs

-111mm Pin heatsink : 1.25lbs entire array with driver 8.772lbs

I am ok with a margin of error for this video. However, if guys that know whats up like you Robin, Pos, GG, SDS, Purplebuzz, Alesh ,Church, SUp tell me my methods are flawed. Ill pull down the video.

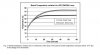

Damn those are loooong. Takes away some vertical space in a tent. But those could easily run 2400ma. Says 100-120watts ! That's almost a CXB3590's max!Apparently the pin heat sinks perform especially well when tilted, as with a spotlight. When vertical, they're similar to other circular heat sinks. At least that's what MechaTronix says in their pin type section. But look at these primo ones on their site for high bays.

And those are radial sinks. Not pin.Apparently the pin heat sinks perform especially well when tilted, as with a spotlight. When vertical, they're similar to other circular heat sinks. At least that's what MechaTronix says in their pin type section. But look at these primo ones on their site for high bays.

Precisely. Look how low the thermal resistance is compared to pin.And those are radial sinks. Not pin.

This is just food for thought, not a criticism, per se.Thanks Robin.

-36" L 5.886 HSusa profile: 9lbs

-111mm Pin heatsink : 1.25lbs entire array with driver 8.772lbs

I am ok with a margin of error for this video. However, if guys that know whats up like you Robin, Pos, GG, SDS, Purplebuzz, Alesh ,Church, SUp tell me my methods are flawed. Ill pull down the video.

octagons ?Your Next Project Is To Construct A Square Heat With Square Pins. Shhhhhhhh Its A Secret

Omg you're FABRICATING your OWN Hollow Pinned sink?!?!@tags420 thanks for the post and the links to do some further research on the topic. I agree, the 5.886" was the go to for a lightly active (small fan on 5v) with the passive safety net. Seems like these days everyone is obsessed with "being passive" for one reason or another, while expecting to get Supra's efficiency numbers at high Tc. And I agree, nothing to worry about with this tried and true set up.

@Nu-Be I have seen high-end PC guys go to great lengths to get a matting surface that was flat within 0.001" I can machine a surface close to one or two thousands, but man, its a lot of time and work. You bring up a great point, long extruded heatsinks aren't perfectly flat unless surface machined, its just not in the nature of the extrusion process with aluminum.

View attachment 3671791

pin sinks perform best when angled or tilted. but what if the pins were hollow? would this be enough of a convection current or draft to improve its performance, i guess we shall find out.

View attachment 3671799

yeah brother, I got a lot of projects like that on my desk.. i try to post about them sparingly, cuz it gets a little old when people are like...Omg you're FABRICATING your OWN Hollow Pinned sink?!?!

That carbon fiber??