What statistics do you use the determine which cob is most efficient then?

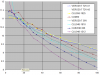

i compare them relatively, same spectrum same temps. i dont care if the top one is 50, 55, 60, 65% whatever if its better than the others. also i can tell that for example a 1212 is going to put out 90% of the light of an 1825 at a given wattage, and if i want 1212 s to have the same efficiency as an 1825 i need to run 50% of the same wattage per cob, things like that. at the end of the day a cob is a cob and once you select spectrum, your efficiency is going to be determined by a whole host of factors including current, heat sink design, ambient air temp, air flow, etc etc. but i can predict how cob A will perform relative to cob B in the same setup and thats what im after

for example you could take two fixtures, one with a black pin fin and one with a white pin fin and they will give different numbers in the sphere as the high surface area pinfin absorbs photons. stuff like that.

i think the real world curves i generate are more accurate than say a calculator because the allow for real temperature measurement. for example you could pull up cree pct and see a whole range of efficiencies plotted out based on current but it doesnt work like that, as its assuming that the chip is running same temp at 1.4A as it is at 3.6A. you can adjust Tj manually but at that point youre guessing as a ceramic cree flows heat differently than all the aluminum substrate chips. even the citi calculator that calculates Tj for you automatically based on current and Tc still needs you to guess at Tc

in the end, nothing short of a real world test will tell you how these chips perform. i got the sphere months ago and i have everything i need to get PAR measurements and lumen measurements including multiple photodiodes, tungsten calibration lamp, multiple spectrometers (its a whole different setup to calibrate it to measure absolute lumens- its 100x more easier to measure par directly with a calibrated li-cor- but even that is biased against 90 cri chips with spectra over 700 - so the goal is to work within our limits and generate standardized useful repeatable measurements.

so i control what i can. 4000k 80 cri is the control spectrum. that spectrum is commonly available as samples in all cobs, and has little outside of 400-700 to skew the par measurement. we are literally measuring the electrical and thermal component of the chip so its not worth testing every phosphor combo

im ordering some DB bin 4000k 80s from jerry today (and DB 3500k that nobody around here ever wants to cough up for testing) so well see whats up soon. ideally id have a waterblock to mount the cobs to but ill probably just use iceleds as they do a good job of keeping the heatsinks really uniform in temp to allow for better measurements.ill document it well so you guys can offer suggestions on how to improve the technique.

so heres what i will have in 4000k 80 for the definitive shootout... only thing im missing right now is time and i need this hellacious winter to end and stop fucking myself up. To do this right is about 40+ hours of work just to get the data but we will learn a lot

4000k 80:

3590 DB

1212 gen 5

1212 gen 6

1818 gen 5

1818 gen 6

1825 gen 5

1825 gen 6

3618 gen 5 (i think)

3618 gen 6

cxm 22

cxm 27

cxm 32

vero B (i think)

vero C

vero D

thats what im contribuitng. if you guys have any other chips you want to see in the test send them my way. ideally id do multiple chips for each test to account for binning/variation but there are some like the luminus that i only have one of as it was damn near impossible to get samples from them. maybe ill have better luck now that ive dropped a bunch of loot with them