What did you accomplish today?

- Thread starter 420God

- Start date

Singlemalt

Well-Known Member

Describe the set up and your methodology. Were all beakers to have the same concentration of yeast and of molasses, so each beaker was an alleged identical to each other beaker? Or did each beaker have a diff. conc of yeast and or molasses? All done at the same time?It's a fermentation lab, just as when alcohol is produced. It was molasses with yeast added to it.

cannabineer

Ursus marijanus

Aww man with the right doors you could restore a Sukhoi in thereI want a shed like thisView attachment 4354523

You know what for (so many power points)

Skeet Kuhn Dough

Well-Known Member

No, the concentration was the same, although each beaker had a different pH level. The idea was to see how pH affects the outcome (the amount of CO2 gas that is produced, ie the amount of fermentation that occurred).Describe the set up and your methodology. Were all beakers to have the same concentration of yeast and of molasses, so each beaker was an alleged identical to each other beaker? Or did each beaker have a diff. conc of yeast and or molasses? All done at the same time?

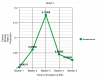

Beaker #3 started with a pH of between 5-6 (our's was 5). It produced the most CO2. They were placed in an incubator at 45C for a little over 45 minutes.

Skeet Kuhn Dough

Well-Known Member

Nevermind the .pdf attempt, this is easier, though it looks a little off.Describe the set up and your methodology. Were all beakers to have the same concentration of yeast and of molasses, so each beaker was an alleged identical to each other beaker? Or did each beaker have a diff. conc of yeast and or molasses? All done at the same time?

The Effect of Temperature on the Rate of Carbon Dioxide Production in Saccharomyces

Abstract

We have concluded that a pH between 5 and 6 is best for fermentation for alcohol by using various pH levels in five different test tubes. By recording their starting conditions and then measuring their results afterwards, we will be able to see how much CO2 was produced, showing us which starting pH is most effective.

Introduction

Homo sapiens have been using fermentation to create alcoholic beverages for many years now. In this paper I will discuss which pH balance works best to this end. Carbon dioxide production in yeast can be affected by temperature and potential hydrogen, pH. I will be using five different beakers to with varying starting levels of pH. They will all be incubated at the same temperature at the same time while having pH levels that are different. In this lab, we will have no direct method of measuring gas. We can instead use water to show how much CO2 was made and the fermentation rate (Schweinitz).

Materials

· 1 medium beaker (approximately 300-500 ml capacity)

· 5 small beakers labeled 1 through 5 (80-120 ml capacity)

· 5 fermentation tubes labeled with group letter and numbered 1 through 5

· 1 medium graduated cylinder (50 ml)

· 1 small graduated cylinder (10 ml)

· 1 hydrometer and hydrometer tube

· 5 glass stirring rods

· Wax pencil

· 2.0 M Citric acid solution (dropper bottle)

· 0.3 M Calcium hydroxide solution (dropper bottle)

· pH paper test strips

· gloves (latex)

Method

The first step was to pour 150 ml of the yeast/molasses mixture into a medium beaker while continuously stirring the flask.

The second step was to take the beaker to the lab table while continuing to swirl. We used the graduated cylinder to transfer exactly 30 ml of the mixture into each of the 5 beakers which we labeled 1 through 5. All of the beakers received the same quantity and concentration of the yeast/molasses mixture.

Thirdly, we used pH paper which helped us to ascertain the pH of the mixture in beaker 3. The pH was recorded at 5. Beaker 3 became our control mixture and we never changed its pH level. We would record the data.

We next added citric acid, given a few drops at a time to beaker 2, stirring and checking pH until we reached a pH of 4.0. We recorded the data.

We then moved on to baker 1, adding the same number of drops of citric acid as used previously. This continued until a pH of 2.0 was given. Data was recorded.

Now we moved on to beaker 4, adding calcium hydroxide this time. We got the pH of beaker 4 to 8.0. We also did this to beaker 5, only we upped the pH to 10.0. All data was recorded.

For our next step, we measured and recorded the specific gravity of beaker number 3 by using a hydrometer. All beakers had the same specific gravity and so we recorded it thusly. To record the specific gravity, we poured the yeast mixture form the beaker into the hydrometer tube until it was two-thirds of the way full. We then inserted the hydrometer without letting it hit the bottom of the tube whilst also dislodging any bubbles. After recording the specific gravity, we removed the hydrometer and returned the mixture to the beaker.

At this point we returned the solutions from the five beakers to the appropriately labeled fermentation tubes without any bubbles.

All fermentation tubes were then placed in the incubator at time 1939, where they would be incubated at 45C until a time of 2045, a time of 46 minutes.

Immediately after removing the fermentation tubes from the incubator, we marked the gas level on the fermentation tube with a wax pencil after ensuring that the tubes were sitting flat on the table so that we could be as accurate as possible.

We then documented that 46 minutes had passed since incubation first began.

After that, we poured the contents of the fermentation tube into the hydrometer tube and measured the final specific gravity.

At this point we measured the volume of gas collected in the fermentation tube by adding a small amount of water to the tube and then inverted it so that the water leveled off to the mark we made earlier. By moving the water to a graduated cylinder we were able to record the volume of CO2 by measuring the water. We did this for all of the fermentation tubes and recorded the data.

Hypothesis

Each difference in pH will yield a varying amount of CO2.

Prediction

I predict that the best pH will be between 5 and 6; this correlates to beaker 3.

Results

Citations

Schweinitz, Jean. Majors Biology Laboratory Manual. Second Edition. 2009, 2010. Kendall Hunt Publishing Company.

depends what you mean by haole XD cause most people misuse it and say it to white people kind of like "cracker" but haole means your just an outsider in general doesn't matter the race.So, you're a haole?

and no i wouldn't be considered a haole and if a mfer ever called a haole we'd square up real quick. it's like calling a black person a nigger basically but haole again is mostly misused and said to white people and i am white.

Singlemalt

Well-Known Member

@Skeet Kuhn Dough

A couple questions: 1) why did you do this @45C? That's pretty damn hot, yeast function much better below 32C.

2) More a statement, relabel the graph to pH instead of beaker #

3) Is the class Biology for Non Science Majors?

A couple questions: 1) why did you do this @45C? That's pretty damn hot, yeast function much better below 32C.

2) More a statement, relabel the graph to pH instead of beaker #

3) Is the class Biology for Non Science Majors?

Singlemalt

Well-Known Member

Were you born there? My sister lives in Hawaii and she said the "native" (Pacific Islanders) Hawaiians are hardcore, even Japanese and Chinese who've been there many generations are still treated as foreignersdepends what you mean by haole XD cause most people misuse it and say it to white people kind of like "cracker" but haole means your just an outsider in general doesn't matter the race.

and no i wouldn't be considered a haole and if a mfer ever called a haole we'd square up real quick. it's like calling a black person a nigger basically but haole again is mostly misused and said to white people and i am white.

accidentally took a nap woke up it was extremely humid, dark and i was in a puddle of sweat. supposed to storm tonight but knowing our luck that aint gonna happen usually doesn't get this dark until around 7 during the summer but it's only 5 when i woke up.

got to do some cannabis research later on probably won't do that tonight though cause once i get into it i can't get out i spend hours just doing research. gotta order some scrog nets soon so they come in time when i need them. not sure if found a cavity or what but my tooth has been aching for a long time whenever i bite down/eat food so i decided to get one of those dentist picks with the hook cause what i thought it was seems like it was the reason. which is basically there is this small gap on the top row right next to my metal filling that i thought was a cavity and i started to just dig around and got tiny bits of food stuck deep within my gums and that tiny gap causing it to hurt like a mfer. basically just felt like having popcorn kernels stuck in your gums very uncomfortable and when i chewed slight pain but i guess that was from the food getting lodged deeper into the gums. after i cleaned that up it feels good and new

got to do some cannabis research later on probably won't do that tonight though cause once i get into it i can't get out i spend hours just doing research. gotta order some scrog nets soon so they come in time when i need them. not sure if found a cavity or what but my tooth has been aching for a long time whenever i bite down/eat food so i decided to get one of those dentist picks with the hook cause what i thought it was seems like it was the reason. which is basically there is this small gap on the top row right next to my metal filling that i thought was a cavity and i started to just dig around and got tiny bits of food stuck deep within my gums and that tiny gap causing it to hurt like a mfer. basically just felt like having popcorn kernels stuck in your gums very uncomfortable and when i chewed slight pain but i guess that was from the food getting lodged deeper into the gums. after i cleaned that up it feels good and new

UncleBuck

Well-Known Member

yea im born and raised here on Oahu i literally still live in the same house for the past 26 years. yea they tend to be more aggressive to Japanese imo cause the Japanese here are what you'd consider "privelaged" they walk around like they own the place i've worked with Japanese tourists many times they are more humble then the ones born and raised here which is very sad. as for the chinese idk i guess cause there is so many of um people feel threatened like they taking over the place. our neighbors are from china they don't bother us. the house down the street went for sale earlier this year chinese people bought it they don't bother us. the gas station across the street from my house has a SHIT load of chinese in the morning cause thats where they all meet up to get picked up for work none of them bother me.Were you born there? My sister lives in Hawaii and she said the "native" (Pacific Islanders) Hawaiians are hardcore, even Japanese and Chinese who've been there many generations are still treated as foreigners

but yea if you like provoke them then good luck cause yea they can get pretty aggressive. nobody ever calls me a haole though well no stranger. the only people that has ever called me a haole to my face was my dad who misuses the term and you can ask him yourself but i punched him for it not playfully like we get into actual fist fights and my uncle but can't punch my uncle plus that uncle is weird af he is always grouchy. don't matter they hawaiian or not we gon square up if the mfer calls me haole lmfao. Most hawaiians are actually i guess you can say "mudblood" since they are not 100% Hawaiian. they are all mostly mixed now so they tend to try and flaunt that they are Hawaiian but might only be like 1% hawaiian.

where does she actually live? Here on Oahu they don't really do shit then again most people on Oahu are asian on Maui when i went i was surprised to see so much white people like you DONT see that many white people here unless you go to like waikiki

techinically yes i am but so is like 99% of the population. i was saying i would NOT be considered a haole here. the white part is inaccurate. it only pertains to non natives which is majority of the states population. it is MAINLY used as a racial slur though thus why not many people use it anymore it's literally like calling a black person a nigger.

Skeet Kuhn Dough

Well-Known Member

1. Answer: We did this at 45C because that was the Lab Instructions. This paper was based upon results that were yielded in a lab experiment. The temp was predetermined, not by the students, not by the professor, but by the lab manual.@Skeet Kuhn Dough

A couple questions: 1) why did you do this @45C? That's pretty damn hot, yeast function much better below 32C.

2) More a statement, relabel the graph to pH instead of beaker #

3) Is the class Biology for Non Science Majors?

2. Answer: We were given instructions about the graph. Not sure if I deviated or not but I've already submitted the paper electronically. I could resend it, I doubt it will help. I've no idea what I'm talking about/doing. This much coursework in five weeks is kickin' my arse.

3. Answer: No, it is for actual Science Majors. Several future doctors and psychologists in there. Lots of smarties. I should have just waited to take this in the fall semester.

raratt

Well-Known Member

The 1865 Dictionary of the Hawaiian Language, compiled by Lorrin Andrews, shows the pronunciation as ha-o-le. A popular belief is that the word is properly written and pronounced as hāʻole, literally meaning "no breath," because foreigners did not know or use the honi (hongi in Māori), a Polynesian greeting by touching nose to nose and inhaling or essentially sharing each other's breaths, and so the foreigners were described as breathless. The implication is not only that foreigners are aloof and ignorant of local ways, but also literally have no spirit or life within. Edit: After further research that theory was debunked, and the word is used to describe someone not from Hawaii.

Last edited:

UncleBuck

Well-Known Member

nahit's literally like calling a black person a nigger.

ANC

Well-Known Member

well, it is 6:42am and I already had a joint of northern lights, followed by a joint of exodus.

Feeling a little rough as we went to a trance party yesterday, I'm not sure all the molly has quite worked through my system yet.

Was a good stress relief after a week of harvesting and trimming.

The last time I went was Sept last year.

Feeling a little rough as we went to a trance party yesterday, I'm not sure all the molly has quite worked through my system yet.

Was a good stress relief after a week of harvesting and trimming.

The last time I went was Sept last year.

Singlemalt

Well-Known Member

Konayea im born and raised here on Oahu i literally still live in the same house for the past 26 years. yea they tend to be more aggressive to Japanese imo cause the Japanese here are what you'd consider "privelaged" they walk around like they own the place i've worked with Japanese tourists many times they are more humble then the ones born and raised here which is very sad. as for the chinese idk i guess cause there is so many of um people feel threatened like they taking over the place. our neighbors are from china they don't bother us. the house down the street went for sale earlier this year chinese people bought it they don't bother us. the gas station across the street from my house has a SHIT load of chinese in the morning cause thats where they all meet up to get picked up for work none of them bother me.

but yea if you like provoke them then good luck cause yea they can get pretty aggressive. nobody ever calls me a haole though well no stranger. the only people that has ever called me a haole to my face was my dad who misuses the term and you can ask him yourself but i punched him for it not playfully like we get into actual fist fights and my uncle but can't punch my uncle plus that uncle is weird af he is always grouchy. don't matter they hawaiian or not we gon square up if the mfer calls me haole lmfao. Most hawaiians are actually i guess you can say "mudblood" since they are not 100% Hawaiian. they are all mostly mixed now so they tend to try and flaunt that they are Hawaiian but might only be like 1% hawaiian.

where does she actually live? Here on Oahu they don't really do shit then again most people on Oahu are asian on Maui when i went i was surprised to see so much white people like you DONT see that many white people here unless you go to like waikiki

Laughing Grass

Well-Known Member

Singlemalt

Well-Known Member

Not just youIs it just me or is the site badly broken. Been getting timeouts since yesterday evening on all devices. Only thing that works is hola from the UK.

it won't let me delete or change my avatar grrr! connection timeout.

edit. Seems to be a lot of countries that are having issues.

View attachment 4354671

Laughing Grass

Well-Known Member

Seems to be working from the notebook now. The site loads on my phone but I can't login, no error it just returns to the homepage.Not just you