Ain't doable with solder iron ,hot air gun ,reflow oven ,etc ....

Well ,Stardusty find out a really easy way to do it ...

...

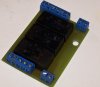

This is the reworking station :

.....

In order to rework mcpcbs placed on heatsink ,you need :

- A Small

camping gas stove .Or how it is called ,anyway ....

- A

Powerful fan .

-Something to keep steady the heatsink ...I.e .

a vice ...(I do not have one,right now !!!! ..)

- A

solder iron .Or hot air gun ....

-

Tweezers .

-

High Temp.Thermocouple .Here used polymeter's type K thermocouple .Or IR/laser thermometer ,will do fine ...

-

High temp tape .

-

Anti-static bracelet (weared on other hand ,of the working hand ..Left at mi case ...)

-

Solder paste ,flux paste & de-solder wick .

-

Matches .

-

Great caution ,not to cause yourshelf severe burns ...Or set your house on fire ....

Myshelf used to forge ,so I'm kinda used working with burning hot metal chunks ....

Now ....Place the gas stove under the area that needs reworking .....

You are supossed to have already placed nearby this area the thermocouple sensor with heat-resistant tape (i.e. Kapton )

......

Fire the gas ,at max gas flow .......

See how the temps rises slowly at the beginning ....

When temp have reached about 180°C ,get your stuff ready ....

From here you can work the pcb with solder iron ...

You have to lower the gas flow .....

You have about ~ 40 sec time .

Then you'll have to switch off the gas ,turn on the fan and wait until it drops to 100°C .

to re-heat ,if there's more work to do .....

This is not for replacing leds ,but for removing excess solder ,soldering wires ,etc .....

For removing and replacing leds ,there are two ways ....

Depends on the situation which one to choose ...

Done both of them ...

Both work great ....

Way A " The Orthodox Way " ....

After temp has reached ~180°C ,let gas at max until ~ 240 °C .Then switch off .

You have ~ 20 sec to remove led and with a cotton battonette the excess solder from pad if any ...

When finish ,put your hand in front of pcbs and switch on the fan°C at max speed ...

You've to protect the leds from air ,because air stream might move them from position ...

Keep your hand there until temp drops at ~ 180....

Cool down heatsink to ambient ....

Place solder paste with stencil...

Place new led into position .....

Repeat the whole procedure ,until reflowing ....

Way B " I'm kinda stoned & bored " way ....

After temp has reached ~225°C ,lower gas a bit down ....

It will slowly rise up to ~240 ° .Idealy in ~ 20 secs ...

Remove led fast ...

Do not wipe off excess solder ...

Take new led with tweezers ....

Check polarity ...

Gently touch led bottom into solder flux .just a tiny touch....

Place quickly led in position ( pad ) ...

Adjust / trim into position fast ,if needed ...

Switch off gas...

Wait for 5-8 sec ...

Turn on fan at max ...With your hand protecting the

pcbs ..Not just the replaced led...

Finished ...

Not very difficult ...

Well...Did it once on an empty heatsink :

-to check temp rise and drop rates ....

-Gas stove abilities in increasing temps for that exact heatsink ...

-Take a general idea ....

Second time did it on box#1 .....

Success ....

Third time did it on box#2 ...

Success ....

Great method ...

Working with leds ....

Never expected to set them on fire .....

Life's full of suprises ....

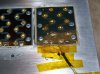

After the " surgery " ....

The removed "organs " ....

Kept for "autopsy" & "anatomy lessons "...

-Note : Althought they seem "burned" they're not ...

That carbon /brown burned color is because of solder flux of paste .

Once cleaned with IPA ,leds shine like new underneath this residue ..

In fact ..those ceramic type of leds ....They can tolerate enough "abuse " ...

They are made exactly for that ....

..

..