Guzias1

Well-Known Member

I will be editing this post with details later tonight, just thought I would get things rolling though :]

This thread is open to all the the enthusiasts out there.. Feedback, safety tips, helpful tips, and overall positive reinforcement for the less educated individuals is our goal here..

DISCLAIMER:

This is a potentially very dangerous process.. And it is highly encouraged to have all your materials ready before you start.. Please, be smart, be safe, and enjoy!

Major Parts:

3+ cfm vacuum pump

regulators for vacuum

desiccator

tube

5x + refined butane

butane is highly flammable, plan out your pull, no smoking while blasting and boiling off butane!

For a smoother quality extraction, i recommend using broken down buds, or sugar leaf trim, you should be able to judge the product by eyes.. A noticeable amount of trichomes should be visible.. ..

For a smoother quality extraction, i recommend using broken down buds, or sugar leaf trim, you should be able to judge the product by eyes.. A noticeable amount of trichomes should be visible.. ..

I packed about 7-8 grams of bud, and minimal trim (pictured) into a stainless steel turkey baster from BBAB... I took 2 coffee filters, put them flat on top of each other, folded the two sheets over once, (makes 4 layers of filters) but then i proceeded, and folded that in half (making 8 layers of filters).. wrapped the 8-layer filter around the bud opening of the turkey baster, then wrapped tape around filter to attach it to tube, ( a metal hose clamp is recommended instead of the tape).. blasted about 1/3 of a can of butane through the tube, spinning it around, shaking it, pausing, just having fun ..

..

i pre folded some parchment paper to hold my sprayed butane, and placed that on a heat pad set to the 120s (before spraying).. I let the heat pad stay on till only a thin layer of liquid was left evaporating..

i pre folded some parchment paper to hold my sprayed butane, and placed that on a heat pad set to the 120s (before spraying).. I let the heat pad stay on till only a thin layer of liquid was left evaporating..

while the heat pad was cooling, the butane had a nice amount of time to boil out.. took about 10 minutes or so to cool down..

while the heat pad was cooling, the butane had a nice amount of time to boil out.. took about 10 minutes or so to cool down..

(picture A)this is the sprayed product, after about 30 minutes after spraying, sticky, but stable at room temperature (wont slide around).

(picture A)this is the sprayed product, after about 30 minutes after spraying, sticky, but stable at room temperature (wont slide around).

I am not positive, but i believe achieving this oil muffin is one of the key factors in letting you know you are going to get a wax, honeycomb... ... ONCE you got product stable at room temperature, it is now time to turn it into a hand touchable solid muffin ball.. to do so, i put (picture A) my paper straight into my vacuum chamber, turn on the vac to full pump. the oil expands, and basically keeps expanding till it reaches a solid balloon type state, its actually multiple see-through bubbles, but we will call them balloons(not to be confused with muffins).. I then release the pressure and the bubbles, fall back down into what looks like a dryer picture A.. i then repeat the vacuum process over and over until it does not rise anymore.. I then take picture A out, and work the oil towards the center of the paper, to do so, i fold the paper over rand over, trying to get a solid puck of oil.. once i get my puck, i throw back into chamber to full vac again..

the bubbles eventually turn smaller and smaller, and the product becomes stiffer and stiffer as you repeat the previous process over and over, and you eventually start to see a nice big muffin start to form... CAUTION, the oil expands 10X + as you vacuum it, so you need to be ready to shut off the vacuum before your oil hits something thats not parchment paper..

the bubbles eventually turn smaller and smaller, and the product becomes stiffer and stiffer as you repeat the previous process over and over, and you eventually start to see a nice big muffin start to form... CAUTION, the oil expands 10X + as you vacuum it, so you need to be ready to shut off the vacuum before your oil hits something thats not parchment paper..

and after many many vacs, and devacs, and foldings of oil back into center of paper, i was finally able to get my solid muffin( muffin is solid when you can touch the muffin, and it doesnt stick to you or shrink.... Notice how tiny it is, this is good, i feel every time i cut this step short, or i never get the solid muffin, i never end up with wax, and usually end up with an oil..

and after many many vacs, and devacs, and foldings of oil back into center of paper, i was finally able to get my solid muffin( muffin is solid when you can touch the muffin, and it doesnt stick to you or shrink.... Notice how tiny it is, this is good, i feel every time i cut this step short, or i never get the solid muffin, i never end up with wax, and usually end up with an oil..

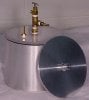

i then prepare a hot water bath in a pyrex big enough to hold my mason vacuum chamber. Hot water bath is heated by a controlled temperature pancake griddle.. I have a laser thermometer to let me know how hot my water is.. I Then place my stable muffin into my vacuum chamber, and melt down the muffin with my water temps at 130F and 5-10hg.. i melt it down till is see a pretty flat puddle, (takes 5-60 minutes depending on how much oil you are making, or even longer) i then turn on my vacuum to full pump, the oil expands into those balloons erratically for a second before maxing out, then those balloons slowly pop and the balloons eventually mellow out to a purging oil.. ( if your vacuum is too small, or if you did not heat your oil hot enough, your balloons may get too big, potentially hitting your chamber, so let off vac, and let your oil get a little warmer, then try again.. and again, till you get mellow out oil) once i reach this point, i dropped full vac to 26-27hg and the temps in my water to 114-117 for a few hours..

i then prepare a hot water bath in a pyrex big enough to hold my mason vacuum chamber. Hot water bath is heated by a controlled temperature pancake griddle.. I have a laser thermometer to let me know how hot my water is.. I Then place my stable muffin into my vacuum chamber, and melt down the muffin with my water temps at 130F and 5-10hg.. i melt it down till is see a pretty flat puddle, (takes 5-60 minutes depending on how much oil you are making, or even longer) i then turn on my vacuum to full pump, the oil expands into those balloons erratically for a second before maxing out, then those balloons slowly pop and the balloons eventually mellow out to a purging oil.. ( if your vacuum is too small, or if you did not heat your oil hot enough, your balloons may get too big, potentially hitting your chamber, so let off vac, and let your oil get a little warmer, then try again.. and again, till you get mellow out oil) once i reach this point, i dropped full vac to 26-27hg and the temps in my water to 114-117 for a few hours..

i had this after a few hours ( i worked material back to center) got a nice soild taffy, shatter?

i had this after a few hours ( i worked material back to center) got a nice soild taffy, shatter?

i then raised the heat to 125 and vac to 29 hg for about 30 min.. product started waxing up too fast i feel ( i hate sparkly crackly bho!) so i dropped temp to 120, and 28 hg for a couple hours.. After that, i raised temps to 14-126 and vac to 29hg

i then raised the heat to 125 and vac to 29 hg for about 30 min.. product started waxing up too fast i feel ( i hate sparkly crackly bho!) so i dropped temp to 120, and 28 hg for a couple hours.. After that, i raised temps to 14-126 and vac to 29hg

got this jsut before going to bed, so i dropped temps to about 122, and put her at full vac, feel asleep..

got this jsut before going to bed, so i dropped temps to about 122, and put her at full vac, feel asleep..

woke up to this! yey! success, thanks to good starting material!

woke up to this! yey! success, thanks to good starting material!

so that my tutorial.. i was not shooting for a massive pull, i was just trying to demonstrate the most simplest cheapest way i have found to make some very potent, awesome concentrates!

so that my tutorial.. i was not shooting for a massive pull, i was just trying to demonstrate the most simplest cheapest way i have found to make some very potent, awesome concentrates!

heres a vid of the melt shot. yeeee and the buds under the wax are the buds i used to make the wax

http://www.youtube.com/watch?v=QktXtCOzuXI

final results:

7.5 grams in

1.18 out

This thread is open to all the the enthusiasts out there.. Feedback, safety tips, helpful tips, and overall positive reinforcement for the less educated individuals is our goal here..

DISCLAIMER:

This is a potentially very dangerous process.. And it is highly encouraged to have all your materials ready before you start.. Please, be smart, be safe, and enjoy!

Major Parts:

3+ cfm vacuum pump

regulators for vacuum

desiccator

tube

5x + refined butane

butane is highly flammable, plan out your pull, no smoking while blasting and boiling off butane!

For a smoother quality extraction, i recommend using broken down buds, or sugar leaf trim, you should be able to judge the product by eyes.. A noticeable amount of trichomes should be visible.. ..

For a smoother quality extraction, i recommend using broken down buds, or sugar leaf trim, you should be able to judge the product by eyes.. A noticeable amount of trichomes should be visible.. .. I packed about 7-8 grams of bud, and minimal trim (pictured) into a stainless steel turkey baster from BBAB... I took 2 coffee filters, put them flat on top of each other, folded the two sheets over once, (makes 4 layers of filters) but then i proceeded, and folded that in half (making 8 layers of filters).. wrapped the 8-layer filter around the bud opening of the turkey baster, then wrapped tape around filter to attach it to tube, ( a metal hose clamp is recommended instead of the tape).. blasted about 1/3 of a can of butane through the tube, spinning it around, shaking it, pausing, just having fun

i pre folded some parchment paper to hold my sprayed butane, and placed that on a heat pad set to the 120s (before spraying).. I let the heat pad stay on till only a thin layer of liquid was left evaporating..

i pre folded some parchment paper to hold my sprayed butane, and placed that on a heat pad set to the 120s (before spraying).. I let the heat pad stay on till only a thin layer of liquid was left evaporating.. while the heat pad was cooling, the butane had a nice amount of time to boil out.. took about 10 minutes or so to cool down..

while the heat pad was cooling, the butane had a nice amount of time to boil out.. took about 10 minutes or so to cool down.. (picture A)this is the sprayed product, after about 30 minutes after spraying, sticky, but stable at room temperature (wont slide around).

(picture A)this is the sprayed product, after about 30 minutes after spraying, sticky, but stable at room temperature (wont slide around).I am not positive, but i believe achieving this oil muffin is one of the key factors in letting you know you are going to get a wax, honeycomb... ... ONCE you got product stable at room temperature, it is now time to turn it into a hand touchable solid muffin ball.. to do so, i put (picture A) my paper straight into my vacuum chamber, turn on the vac to full pump. the oil expands, and basically keeps expanding till it reaches a solid balloon type state, its actually multiple see-through bubbles, but we will call them balloons(not to be confused with muffins).. I then release the pressure and the bubbles, fall back down into what looks like a dryer picture A.. i then repeat the vacuum process over and over until it does not rise anymore.. I then take picture A out, and work the oil towards the center of the paper, to do so, i fold the paper over rand over, trying to get a solid puck of oil.. once i get my puck, i throw back into chamber to full vac again..

the bubbles eventually turn smaller and smaller, and the product becomes stiffer and stiffer as you repeat the previous process over and over, and you eventually start to see a nice big muffin start to form... CAUTION, the oil expands 10X + as you vacuum it, so you need to be ready to shut off the vacuum before your oil hits something thats not parchment paper..

the bubbles eventually turn smaller and smaller, and the product becomes stiffer and stiffer as you repeat the previous process over and over, and you eventually start to see a nice big muffin start to form... CAUTION, the oil expands 10X + as you vacuum it, so you need to be ready to shut off the vacuum before your oil hits something thats not parchment paper.. and after many many vacs, and devacs, and foldings of oil back into center of paper, i was finally able to get my solid muffin( muffin is solid when you can touch the muffin, and it doesnt stick to you or shrink.... Notice how tiny it is, this is good, i feel every time i cut this step short, or i never get the solid muffin, i never end up with wax, and usually end up with an oil..

and after many many vacs, and devacs, and foldings of oil back into center of paper, i was finally able to get my solid muffin( muffin is solid when you can touch the muffin, and it doesnt stick to you or shrink.... Notice how tiny it is, this is good, i feel every time i cut this step short, or i never get the solid muffin, i never end up with wax, and usually end up with an oil.. i then prepare a hot water bath in a pyrex big enough to hold my mason vacuum chamber. Hot water bath is heated by a controlled temperature pancake griddle.. I have a laser thermometer to let me know how hot my water is.. I Then place my stable muffin into my vacuum chamber, and melt down the muffin with my water temps at 130F and 5-10hg.. i melt it down till is see a pretty flat puddle, (takes 5-60 minutes depending on how much oil you are making, or even longer) i then turn on my vacuum to full pump, the oil expands into those balloons erratically for a second before maxing out, then those balloons slowly pop and the balloons eventually mellow out to a purging oil.. ( if your vacuum is too small, or if you did not heat your oil hot enough, your balloons may get too big, potentially hitting your chamber, so let off vac, and let your oil get a little warmer, then try again.. and again, till you get mellow out oil) once i reach this point, i dropped full vac to 26-27hg and the temps in my water to 114-117 for a few hours..

i then prepare a hot water bath in a pyrex big enough to hold my mason vacuum chamber. Hot water bath is heated by a controlled temperature pancake griddle.. I have a laser thermometer to let me know how hot my water is.. I Then place my stable muffin into my vacuum chamber, and melt down the muffin with my water temps at 130F and 5-10hg.. i melt it down till is see a pretty flat puddle, (takes 5-60 minutes depending on how much oil you are making, or even longer) i then turn on my vacuum to full pump, the oil expands into those balloons erratically for a second before maxing out, then those balloons slowly pop and the balloons eventually mellow out to a purging oil.. ( if your vacuum is too small, or if you did not heat your oil hot enough, your balloons may get too big, potentially hitting your chamber, so let off vac, and let your oil get a little warmer, then try again.. and again, till you get mellow out oil) once i reach this point, i dropped full vac to 26-27hg and the temps in my water to 114-117 for a few hours.. i had this after a few hours ( i worked material back to center) got a nice soild taffy, shatter?

i had this after a few hours ( i worked material back to center) got a nice soild taffy, shatter? i then raised the heat to 125 and vac to 29 hg for about 30 min.. product started waxing up too fast i feel ( i hate sparkly crackly bho!) so i dropped temp to 120, and 28 hg for a couple hours.. After that, i raised temps to 14-126 and vac to 29hg

i then raised the heat to 125 and vac to 29 hg for about 30 min.. product started waxing up too fast i feel ( i hate sparkly crackly bho!) so i dropped temp to 120, and 28 hg for a couple hours.. After that, i raised temps to 14-126 and vac to 29hg got this jsut before going to bed, so i dropped temps to about 122, and put her at full vac, feel asleep..

got this jsut before going to bed, so i dropped temps to about 122, and put her at full vac, feel asleep.. woke up to this! yey! success, thanks to good starting material!

woke up to this! yey! success, thanks to good starting material!  so that my tutorial.. i was not shooting for a massive pull, i was just trying to demonstrate the most simplest cheapest way i have found to make some very potent, awesome concentrates!

so that my tutorial.. i was not shooting for a massive pull, i was just trying to demonstrate the most simplest cheapest way i have found to make some very potent, awesome concentrates! heres a vid of the melt shot. yeeee and the buds under the wax are the buds i used to make the wax

http://www.youtube.com/watch?v=QktXtCOzuXI

final results:

7.5 grams in

1.18 out

Attachments

-

179.9 KB Views: 1,680

-

221 KB Views: 1,538