Templeman420

Member

Hey guys ive been lurking for some time, and finally registered having my first post.

I have a few questions if my setup will work, and your opinions are appreciated.

5 of these

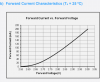

SI-B8UZ91B20WW F-Series Gen3 3500K Linear Light Strip

Current - Test 2.24A

Temperature - Test 65°C

Voltage - Forward (Vf) (Typ) 46V

Current - Max 3.6A

CRI 80

108.4 watt max

1120.00mm L x 39.80mm W

www.digikey.ca

www.digikey.ca

And the driver is Constant Current Hlg-480H-C2100A

95% efficient

1050 - 2100 m/a

481 watt

Open circuit 280v

Voltage - Output 114 ~ 229V

Current - Output (Max) 2.1A

www.digikey.ca

www.digikey.ca

This is a A series driver and my question is if this is going to be an issue?

Thank you for your time.

I have a few questions if my setup will work, and your opinions are appreciated.

5 of these

SI-B8UZ91B20WW F-Series Gen3 3500K Linear Light Strip

Current - Test 2.24A

Temperature - Test 65°C

Voltage - Forward (Vf) (Typ) 46V

Current - Max 3.6A

CRI 80

108.4 watt max

1120.00mm L x 39.80mm W

SI-B8UZ91B20WW Samsung Semiconductor, Inc. | Optoelectronics | DigiKey

Order today, ships today. SI-B8UZ91B20WW – LED Lighting COBs Engines Modules LED Module series White, Warm Linear Light Strip from Samsung Semiconductor, Inc.. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

And the driver is Constant Current Hlg-480H-C2100A

95% efficient

1050 - 2100 m/a

481 watt

Open circuit 280v

Voltage - Output 114 ~ 229V

Current - Output (Max) 2.1A

HLG-480H-C2100A MEAN WELL USA Inc. | Power Supplies - External/Internal (Off-Board) | DigiKey

Order today, ships today. HLG-480H-C2100A – 2.1A 114 ~ 229V Constant Current LED Driver AC DC Converter Topology 1 Output from MEAN WELL USA Inc.. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

This is a A series driver and my question is if this is going to be an issue?

Thank you for your time.