You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can get more addictive ..Can it ?

- Thread starter stardustsailor

- Start date

stardustsailor

Well-Known Member

I have one of the noctua flx, 140 mm nice fan well made and quiet , but I was not impressed with the cfm\static pressure. I'm thinking of running it at 15V instead of 12V.

Since then I picked up a couple of rosewill hypobera, decent pricing and check out the air pressure!

Fan Size: 140mm

http://www.amazon.com/gp/product/B006CSKM20/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1

- Bearing Type: HDB (Hydro Dynamic Bearing)

- RPM: 600 -1300 RPM

- Dimensions: 140 x 140 x 25mm

- Max static air pressure: 2.76 mm H2O

and oh btw do you know how to hook up an led to the tach wire so I can visually see that the fan is working ? My understanding is connect a resistor plus led from 12Vdc to the yellow tach wire But I don't know what ohm resistor and what led to use for a nice bright strobing signal.

At most cases the 'TACH' wire (usually yellow color coded) of a 3 wired fan ,will output two 12 VDC signals

for every rotation of the rotor.

At 1200 rounds per minute ,that translates into 2400 signals per minute .

2400 / 60 = 40 signals per second.

40 'blinks' per second ,of an indicator LED,is translated into almost continuous light ,at the vision center of a human brain.

No strobo effect here....Rather an 'dizzzing' to watch ,rapidly flickering led...

Still ,to connect directly the TACH wire with a small epoxy 20 mA led ,you will need :

12 / 0.02 = 600 Ohm .

Any resistor from 600 Ohm ,up to 1 K will do .

To make a strobo effect ,firstly you will have to select the strobo frequency ...

Say it is 20 Hz (twenty blinks per second ).

Then from Fan rpm and tach signaling (2 pulses for every round or 4 pulses per round ) ,

you will calculate the incoming signals ..|Say for example 2400 per minute .. (40 Hz )

Then you will need a simple IC (very cheap ,less than $1 ) called 4017 decade counter divider .

http://www.doctronics.co.uk/4017.htm

http://www.doctronics.co.uk/pdf_files/hcf4017.pdf

The decade counter/divider IC has 1x signal input and 10x signal outputs ...

Connect the 4017 input with the tach wire ...

Connect outputs 1,3,5,7 & 9 ,(or 2,4,6,8 & 0 ) all at the + pin of the led .(small 20 mA one ).

(reset & enable pins of the 4017 ' lowered to ground '=>connect with " - " line/wire )

At the - ( cathode ) pin of the led connect one 1K resistor .

Now for every incoming signal set of duo ,only for the one pulse the led lights up ..

Actually you 've divided the incoming signal frequency by two .

The led will blink with 20 Hz frequency .

(Perceived as 'strobing light ' .)

For a good 'flash ' choose a large RGB white one and use an 680 ohm resistor instead of 1K.

Cheers.

Last edited:

AquariusPanta

Well-Known Member

wow SDS thats really cool,

I'm gonna put these on all my fans, so that when I peek at my grows to make sure everything is working ok I know right away that the fan is working or not.

At most cases the 'TACH' wire (usually yellow color coded) of a 3 wired fan ,will output two 12 VDC signals

for every rotation of the rotor.

At 1200 rounds per minute ,that translates into 2400 signals per minute .

2400 / 60 = 40 signals per second.

40 'blinks' per second ,of an indicator LED,is translated into almost continuous light ,at the vision center of a human brain.

No strobo effect here....Rather an 'dizzzing' to watch ,rapidly flickering led...

Still ,to connect directly the TACH wire with a small epoxy 20 mA led ,you will need :

12 / 0.02 = 600 Ohm .

Any resistor from 600 Ohm ,up to 1 K will do .

To make a strobo effect ,firstly you will have to select the strobo frequency ...

Say it is 20 Hz (twenty blinks per second ).

Then from Fan rpm and tach signaling (2 pulses for every round or 4 pulses per round ) ,

you will calculate the incoming signals ..|Say for example 2400 per minute .. (40 Hz )

Then you will need a simple IC (very cheap ,less than $1 ) called 4017 decade counter divider .

http://www.doctronics.co.uk/4017.htm

http://www.doctronics.co.uk/pdf_files/hcf4017.pdf

The decade counter/divider IC has 1x signal input and 10x signal outputs ...

Connect the 4017 input with the tach wire ...

Connect outputs 1,3,5,7 & 9 ,(or 2,4,6,8 & 0 ) all at the + pin of the led .(small 20 mA one ).

(reset & enable pins of the 4017 ' lowered to ground '=>connect with " - " line/wire )

At the - ( cathode ) pin of the led connect one 1K resistor .

Now for every incoming signal set of duo ,only for the one pulse the led lights up ..

Actually you 've divided the incoming signal frequency by two .

The led will blink with 20 Hz frequency .

(Perceived as 'strobing light ' .)

For a good 'flash ' choose a large RGB white one and use an 680 ohm resistor instead of 1K.

Cheers.

When it comes to the fans, I like my blades simple, cheap, and ninja-like. . .

http://www.newegg.com/Product/Produ..._re=rosewill_140mm_fan-_-35-200-093-_-Product

It ran with a 5V, 1A PSU (Energizer), with a steady current of just 82mA (that's less than half a watt of juice!). I couldn't hear it make a noise other than its wobbles on the countertop.

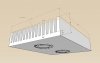

When it comes to the fans, I like my blades simple, cheap, and ninja-like. . .

View attachment 3311969

http://www.newegg.com/Product/Produ..._re=rosewill_140mm_fan-_-35-200-093-_-Product

It ran with a 5V, 1A PSU (Energizer), with a steady current of just 82mA (that's less than half a watt of juice!). I couldn't hear it make a noise other than its wobbles on the countertop.

pretty fan!

Do you know if the red leds are hooked up to the tach signal wire ?

AquariusPanta

Well-Known Member

pretty fan!

Do you know if the red leds are hooked up to the tach signal wire ?

I don't know a bunch about computer fans but when I hooked up the positive and negative wires (just two wires used from the fan), the lights and fan powered on. It appears that each LED relays back to the circuit board, where it shares power with the fan.

stardustsailor

Well-Known Member

200 mm length

160 mm Length (-20 mm per side ),as Salmonetin suggested..

Tj : 70.6 vs 74.3 ...

Tcase : 55.2 vs 58.3

|Pressure drop : 17.346 vs 17.2 Pascal ..

Cutting off 20 mm of heatsink per side only attributes to a lower pressure drop

of ~ 0.146 Pa ..

Final result though,is that Tcase rises 3.1 C as Tj rises 3.7 C.

Cheers.

160 mm Length (-20 mm per side ),as Salmonetin suggested..

Tj : 70.6 vs 74.3 ...

Tcase : 55.2 vs 58.3

|Pressure drop : 17.346 vs 17.2 Pascal ..

Cutting off 20 mm of heatsink per side only attributes to a lower pressure drop

of ~ 0.146 Pa ..

Final result though,is that Tcase rises 3.1 C as Tj rises 3.7 C.

Cheers.

stardustsailor

Well-Known Member

Pot is gone.

Was replaced by a rotary switch .

( Alpha single pole / 12 position )

A pcb for the rotary switch with 12x SMD 1206 resistor pads .

R1 is the min limit current limiter .Set to be a 6.8K ,limiting Io to a min of ~ 300mA for both the drivers.

R2 - R 11 are 3.9K .

R12 is set at 22K ,ensuring a final resistance well above 50K ,thus max output driving current .current .

The calculation estimation is done like this :

Io max =2200 mA

Io max nedss 100 K for one driver ,100K/N for N drivers.

so at 50K for this case is Io max .

For single driver : x *10K = x*10% of Io

For dual drivers : x*5K =x*10% of Io

300 mA is ( 300/2200 *100= ) 13.636 % of Io max .

For a single driver ,a 13.6 K resistance will set this min Io limit .

For dual drivers set up = 13.6 /2 = 6.8 K

The rest :

(10% tolerance 1206 SMD resistors were used )

Switch Position - Calc/estim Io -Measured Real Io- Indicative Io - Total Power at plug

1 -299 mA -290 mA - "300 mA " - 30 W

2 -471 mA -460 mA - "450 mA " - 45 W

3 -642 mA -630 mA - "600 mA " - 60 W

4 -814 mA -800 mA - "800 mA " - 72 W

5 -986 mA -980 mA - "1000 mA " - 85 W

6 -1157 mA -1155 mA - "1150 mA " - 100 W

7 -1329 mA -1330 mA - "1300 mA " - 115 W

8 -1500 mA -1500 mA - "1500 mA " - 130 W

9 -1672 mA -1680 mA - "1700 mA " - 145 W

10 -1844 mA -1850 mA - "1850 mA " - 160 W

11 -2015 mA -2030 mA - "2000 mA " - 175 W

12 -2200 mA -2265 mA - "2200 mA " - 195 W

Was replaced by a rotary switch .

( Alpha single pole / 12 position )

A pcb for the rotary switch with 12x SMD 1206 resistor pads .

R1 is the min limit current limiter .Set to be a 6.8K ,limiting Io to a min of ~ 300mA for both the drivers.

R2 - R 11 are 3.9K .

R12 is set at 22K ,ensuring a final resistance well above 50K ,thus max output driving current .current .

The calculation estimation is done like this :

Io max =2200 mA

Io max nedss 100 K for one driver ,100K/N for N drivers.

so at 50K for this case is Io max .

For single driver : x *10K = x*10% of Io

For dual drivers : x*5K =x*10% of Io

300 mA is ( 300/2200 *100= ) 13.636 % of Io max .

For a single driver ,a 13.6 K resistance will set this min Io limit .

For dual drivers set up = 13.6 /2 = 6.8 K

The rest :

(10% tolerance 1206 SMD resistors were used )

Switch Position - Calc/estim Io -Measured Real Io- Indicative Io - Total Power at plug

1 -299 mA -290 mA - "300 mA " - 30 W

2 -471 mA -460 mA - "450 mA " - 45 W

3 -642 mA -630 mA - "600 mA " - 60 W

4 -814 mA -800 mA - "800 mA " - 72 W

5 -986 mA -980 mA - "1000 mA " - 85 W

6 -1157 mA -1155 mA - "1150 mA " - 100 W

7 -1329 mA -1330 mA - "1300 mA " - 115 W

8 -1500 mA -1500 mA - "1500 mA " - 130 W

9 -1672 mA -1680 mA - "1700 mA " - 145 W

10 -1844 mA -1850 mA - "1850 mA " - 160 W

11 -2015 mA -2030 mA - "2000 mA " - 175 W

12 -2200 mA -2265 mA - "2200 mA " - 195 W

AquariusPanta

Well-Known Member

Hmmm...

Seems Mr."Faster than light ,e fuctrion from old times " is right .....

View attachment 3311407

View attachment 3311408

View attachment 3311409

So ...

Be it ...

View attachment 3311410

View attachment 3311411

The new -age High Intensity ....Diodes ...light ...

Still some ( booooooringgggggg ) wiring -job to be done ...

View attachment 3311412

Yeah it wouldn't make sense to lay the COBs in the same 'river' of air flow, as they would be sharing the same path of heat and thus would be utilizing only a fraction of the HeatSink's volume.

But how will laying the COBs perpendicular to the HS's fins affect the spread of the light? With the way you have assembled it, in comparison to the previous design of COBs running parallel with fins, will the fixture cover the same amount of ground or will it instead sacrifice a little spread for tighter intensity/penetration? (Merely a question every designer/DIY'er should/must ask themselves when coming into focus with the HS/COB layout)

I'm guessing the centroids of the COBS aren't as far apart as they were with the initial designs (100mm and 80mm respectively), as your HS doesn't appear perfectly square (but close). Would you agree that the temperature differences between the three scenarios were miniscule?

Thank you for taking the time to share pictures and links of the Sim program. I'm not sure what I'll be able to accomplish with the 15 'tries' they provide in the trial edition but I may buy into the program if it proves beneficial.

AquariusPanta

Well-Known Member

200 mm length

160 mm Length (-20 mm per side ),as Salmonetin suggested..

View attachment 3312447

View attachment 3312448

View attachment 3312449

Tj : 70.6 vs 74.3 ...

Tcase : 55.2 vs 58.3

|Pressure drop : 17.346 vs 17.2 Pascal ..

Cutting off 20 mm of heatsink per side only attributes to a lower pressure drop

of ~ 0.146 Pa ..

Final result though,is that Tcase rises 3.1 C as Tj rises 3.7 C.

Cheers.

So both scenarios have the COBs' centroids at the same distance apart but just the HS has been shortened in Tin Salmon's design? (200mm vs 160mm)

If that's the case, then I guess you could find that sweet spot that buckles before rolling down the stream of diminishing returns, that would allow you to maximize profits by cutting only down to a certain length of HS, all the while compromising with a optimal case/HS and junction temperature (~50C?).

stardustsailor

Well-Known Member

Yes ...So both scenarios have the COBs' centroids at the same distance apart but just the HS has been shortened in Tin Salmon's design? (200mm vs 160mm)

Requires simple registration ...

Very good tool .

http://www.r-tools.com/

Last edited:

AquariusPanta

Well-Known Member

Your the best SDS!!

stardustsailor

Well-Known Member

AquariusPanta

Well-Known Member

200 mm length

160 mm Length (-20 mm per side ),as Salmonetin suggested..

View attachment 3312447

View attachment 3312448

View attachment 3312449

Tj : 70.6 vs 74.3 ...

Tcase : 55.2 vs 58.3

|Pressure drop : 17.346 vs 17.2 Pascal ..

Cutting off 20 mm of heatsink per side only attributes to a lower pressure drop

of ~ 0.146 Pa ..

Final result though,is that Tcase rises 3.1 C as Tj rises 3.7 C.

Cheers.

I tried out the R-Tools program - it was great!

The biggest obstacle for me was the flow conditions. They give the user 3x options of route and each one is unique. I kept getting high numbers for pressure drop, like ~80 Pa. I'm not entirely sure what that equates to in this situation. Is that due to the fans sucking and blowing air and the air becoming hotter after be thrown in and out of the HS?

Also, if I have 2x fans and added together they make ~100CFM, would I use that as the flow rate? It seemed like when I solved for the flow velocity (RPM x radius of fan), the temperatures across the HS were unbelievably low (like 26C highs).

One more thing I would like to ask: do you use the diameter of the light-emitting surface as your object or do you use the entire COB, ceramic and all?

stardustsailor

Well-Known Member

I tried out the R-Tools program - it was great!

The biggest obstacle for me was the flow conditions. They give the user 3x options of route and each one is unique. I kept getting high numbers for pressure drop, like ~80 Pa. I'm not entirely sure what that equates to in this situation. Is that due to the fans sucking and blowing air and the air becoming hotter after be thrown in and out of the HS?

Equates that something's wrong ...

Two fans ...Also, if I have 2x fans and added together they make ~100CFM, would I use that as the flow rate? It seemed like when I solved for the flow velocity (RPM x radius of fan), the temperatures across the HS were unbelievably low (like 26C highs).

In series (one attached behind the other or in parallel ?

If in series |Flow rate remains same ,air pressure is doubled ..

If in parallel ,pressure remains same,flow rate doubles ...

I'm not sure if " flow velocity =rpm * radius of Fan " is correct ...

It does not seem to be ... ( It seems to be the speed of the rotor wings ,right at their tip )

One more thing I would like to ask: do you use the diameter of the light-emitting surface as your object or do you use the entire COB, ceramic and all?

The total area of the thermal transferring surface ..

For CXA3070 is the whole chip ( 27.35 x 27.35 mm ) ,

for the Vero29 it's thermal pad ( 31.8 x 31.8 mm )

Last edited:

stardustsailor

Well-Known Member

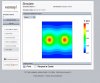

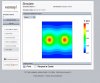

See for example the thermal simulation of those two Vero29 at 2.2 A ,with a heatsink slightly different than the one used and the Noctua NF P-14 FLX fan ...

Tab 1 :

The closer 'substitute' chosen ,to the one actually used .

(they differ also about a kilogram (~ 2 lbs ) weight-wise ..

_All measurements in mm . _

Tab 2 :

Tab 3 :

Air flow of Fan :

110.3 m^3 / h = 110.3 m^3 / 3600 sec = >

Flow rate = 0,030638888889 m^3/sec

Set up : Impinge

(only difference here is the gravity set up ,that can not be changed.But anyway in active cooling ,

position of heat sink in relation to gravity ,is rather detrimental - as opposed in passive cooling. )

TAB 4 :

(Source #2 shown )

Heat power dissipation of Vero29 at 2.2 A = ~ 51.8 Watt = ~52 Watt

Rjc of Vero29 = 0.28 C/W (from datasheet )

TIM : Arctic silver 5 of 8.7 W/m.K therm conductivity .Thick, slobby layer of 250 microns .(worst case chosen here )

Thermal pad of Vero 29 = 31.8 x 31.8 mm =~ 32 x 32 mm

About position ...Find it by yourselves ..

Tip :half of 32 is 16 . Sim software measures from low left chip corner .

Results :

Tab 1 :

The closer 'substitute' chosen ,to the one actually used .

(they differ also about a kilogram (~ 2 lbs ) weight-wise ..

_All measurements in mm . _

Tab 2 :

Tab 3 :

Air flow of Fan :

110.3 m^3 / h = 110.3 m^3 / 3600 sec = >

Flow rate = 0,030638888889 m^3/sec

Set up : Impinge

(only difference here is the gravity set up ,that can not be changed.But anyway in active cooling ,

position of heat sink in relation to gravity ,is rather detrimental - as opposed in passive cooling. )

TAB 4 :

(Source #2 shown )

Heat power dissipation of Vero29 at 2.2 A = ~ 51.8 Watt = ~52 Watt

Rjc of Vero29 = 0.28 C/W (from datasheet )

TIM : Arctic silver 5 of 8.7 W/m.K therm conductivity .Thick, slobby layer of 250 microns .(worst case chosen here )

Thermal pad of Vero 29 = 31.8 x 31.8 mm =~ 32 x 32 mm

About position ...Find it by yourselves ..

Tip :half of 32 is 16 . Sim software measures from low left chip corner .

Results :

Last edited:

churchhaze

Well-Known Member

The thing about spacing multiple light sources on 1 heat sink is that you're optimizing for 2 things.

1) Cooling effectiveness

2) Good light distribution.

Often that means sacrificing a bit of 1 to get more of the other. If you optimize only for cooling factors like even heat sink temperature, you lose flexibility on how you position the lights. Similarly, if you optimize for optimal light distribution, you will sacrifice optimal thermal properties. It's hard to know exactly where the balance is.

If given a choice between slightly better thermal properties or slightly better light distribution, I'd choose the light distribution. That doesn't mean putting them on the outer edges of the longest span of the sink, but somewhat farther apart than perfect cooling.

1) Cooling effectiveness

2) Good light distribution.

Often that means sacrificing a bit of 1 to get more of the other. If you optimize only for cooling factors like even heat sink temperature, you lose flexibility on how you position the lights. Similarly, if you optimize for optimal light distribution, you will sacrifice optimal thermal properties. It's hard to know exactly where the balance is.

If given a choice between slightly better thermal properties or slightly better light distribution, I'd choose the light distribution. That doesn't mean putting them on the outer edges of the longest span of the sink, but somewhat farther apart than perfect cooling.

stardustsailor

Well-Known Member

The thing about spacing multiple light sources on 1 heat sink is that you're optimizing for 2 things.

1) Cooling effectiveness

2) Good light distribution.

Often that means sacrificing a bit of 1 to get more of the other. If you optimize only for cooling factors like even heat sink temperature, you lose flexibility on how you position the lights. Similarly, if you optimize for optimal light distribution, you will sacrifice optimal thermal properties. It's hard to know exactly where the balance is.

If given a choice between slightly better thermal properties or slightly better light distribution, I'd choose the light distribution. That doesn't mean putting them on the outer edges of the longest span of the sink, but somewhat farther apart than perfect cooling.

Totaly respectable choice .

I choose the other way .

For me light output matters most .

Let me explain .

1)

About "light power distribution" ...

How about that one ?

I know that it works pretty fine in spaces like 1 x 1 m ....Enclosed in reflective walls .

I've used myself for some years ..(long ago )

But hey ..They seem kinda same ...nowdays ..

Photons share nothing in common with McGyver .Either they bounce off or get absorbed / transmitted .

Can't escape from an enclosed ,reflective & relatively tight space .McGyver can.Maybe Chuck Norris ,also.

2) Better cooling means higher Vf = higher power output =higher efficiency .

Better cooling means more grow circles done with same units ...Longer service life .

Better cooling means ,more budload .

3) If I 'll face any space & light power distribution issues ,I'll make a twin one .

They can be power adjusted both ....& cover more surface . ..

Although ,one is more than enough for my needs.

Now...

Please enlighten me ,with a better way ,placing two COBs in a small case ,

along with heat sink ,drivers ,fan psu and rest ...Give me your plan of better light distribution ,

with these parts .

Or better yet ,do not be restricted by parts .Show me any other or another alternative .

The one leaning towards 'better light power distribution. Please,give or share with me ,

even the slightest of your ideas .

Thank you.

Cheers.

Similar threads

- Replies

- 52

- Views

- 9K

- Replies

- 48

- Views

- 9K