You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

chilLED: water cooled, ducted, or active led fixture

fearnoevil

Well-Known Member

Cool, do you have any pics? What size pipe, do you solder the plate to the pipe, and is it just a straight shot or do you coil it or otherwise do anything to increase the surface contact area? I like the idea of copper because it withstands corrosion better, and soldered fittings have fewer leak issues ;?)I put copper plates on a copper pipe.

:edit: Ah I should have clicked on the "reply" button. Ah well.

Airwalker16

Well-Known Member

Which cobs are those that's a fucking crazy idea. It works? There's not any issues not being flat against the pipe completely touching?I used 22mm pipe with 40x40x3mm copper plates soldered on.

A picture of a prototype

View attachment 3776823

I used compression couplers.

wietefras

Well-Known Member

Those are CXB3070's. It's not easy to see in the picture, but the COBs are mounted on 3mm thick copper plates which are soldered onto the pipe. Here and there you can see the corners peaking outside of the Ideal holders. So the COBs are actually on a flat copper surface.

I used 22mm pipe with 40x40x3mm copper plates soldered on.

A picture of a prototype

View attachment 3776823

I used compression couplers.

This is sweet but Im not sure it would be any better than standard rectangular aluminum tubing. Would be curious of a side by side comparison of that and an identical one built out of aluminum.

wietefras

Well-Known Member

I doubt there is much performance difference indeed, but didn't have rectangular aluminium tubing. Nor would I know how to weld them together. Copper pipes and all needed fittings are cheap and available everywhere. It's designed to transport warm water around without leaking so I assumed it would be safe.

I'll admit it looks "ghetto", but it works

Actually in the finished product there are several pipes connected for a single flow. This was just a test tube. The full thing is 3 pipes with 8 COBs (400W total).

I'll admit it looks "ghetto", but it works

Actually in the finished product there are several pipes connected for a single flow. This was just a test tube. The full thing is 3 pipes with 8 COBs (400W total).

I doubt there is much performance difference indeed, but didn't have rectangular aluminium tubing. Nor would I know how to weld them together. Copper pipes and all needed fittings are cheap and available everywhere. It's designed to transport warm water around without leaking so I assumed it would be safe.

I'll admit it looks "ghetto", but it works

Actually in the finished product there are several pipes connected for a single flow. This was just a test tube. The full thing is 3 pipes with 8 COBs (400W total).

Who cares if it looks ghetto so long as it works

My only concern would be whether the volume reduction going from the plate through the weld to the pipe would cause a bottleneck or not. For these applications at these temps it might not even be an issue though, idk.

wietefras

Well-Known Member

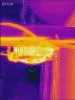

I think it heats up reasonably evenly. Here is a FLIR image from the back of the copper plate:

This thing has two camera's and since I was rather close, the two images don't align exactly. The thermal image is a bit moved to the left compared to the visual overlay. The thermal image itself looks reasonably uniform to me though.

Temperature is stable too. Although of course it depends on the water temperature.

This thing has two camera's and since I was rather close, the two images don't align exactly. The thermal image is a bit moved to the left compared to the visual overlay. The thermal image itself looks reasonably uniform to me though.

Temperature is stable too. Although of course it depends on the water temperature.

nevergoodenuf

Well-Known Member

The only advantage I see with the aluminum is if there was no water in the tube. The aluminum might be enough cooling to still protect the COBs. But very cool idea.

damn, shit just got real:

https://chilledgrowlights.com/independent-lab-reports/gen2-led-grow-light-module-lab-report

https://chilledgrowlights.com/independent-lab-reports/gen2-led-grow-light-module-lab-report

l0wbob2016

Well-Known Member

very nice! these gen2 modules are awesome!

then i just saw this on youtube, its like crazy big quantumboards.24V or 48V @ 100W a panel take a look:

got 330 LED's per panel and 6 panels

how do they ged rid of the heat? or isnt there much heat to get rid off?

then i just saw this on youtube, its like crazy big quantumboards.24V or 48V @ 100W a panel take a look:

got 330 LED's per panel and 6 panels

how do they ged rid of the heat? or isnt there much heat to get rid off?

Last edited:

ScaryGaryLed

Well-Known Member

trust me there's better options. just make something and we'll go from there. we'll help you constructively here.goddamn it between growmau5 and vitaly from chilLED, i'm questioning my own sexuality.

trust me there's better options. just make something and we'll go from there. we'll help you constructively here.

Thanks for the kind words.. I can't wait to start putting pieces together. Do you mid sharing some features of setups you've run?

Similar threads

- Replies

- 454

- Views

- 33K

- Replies

- 7

- Views

- 841

- Replies

- 3

- Views

- 646

- Replies

- 7

- Views

- 1K

- Replies

- 0

- Views

- 389