I decarboxylate and extract into coconut oil in one step.

I use a mason jar (guaranteed heat proof, but only use a wooden stirrer!) inside a small stainless steel container with a perforated spacer at the bottom for the oil bath. (I found it at a thrift store for a couple of bucks.)

I do NOT recommend using a glass container for the oil bath; if it breaks while heated you'll have a nasty fire involving oil at a higher temperature than the melting point of human beings! Get a used metal saucepan at a thrift store. (Aside from the "flames of hell" wok burner I use as a heat source, my total cost for "hardware" was less than ten bucks.)

The outer container is filled up to the same level as the coconut oil in the mason jar. I use a candy thermometer in the coconut oil, not in the outer oil: there is appreciable delay heating something in a glass container, and the temperature of the coconut oil is what matters. (That's another reason to not use glass for the oil bath container.)

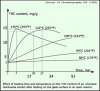

To obtain maximum decarboxylation per the graph, I first heat the coconut oil to 122C/252F and stabilize it there. Go any higher and you will start boiling off the terpenes that have synergistic effects with the cannabinoids, starting with beta-carophyllene, one of the few (perhaps the only) CB2-specific agonists found in pot. A higher temperature also means a sharper inflection point on the THC graph and unless you start with cannabis whose chemical profile is known, you don't know where you're starting. Thus, the choice of 122 C, where the THC content graph is fairly flat at a high concentration. More wiggle room.

Then I add the dried bud (1 gram per tbsp coconut oil, approximately), and cook for about 25 minutes. One can see the bubbles as the CO2 escapes. This is not only TCH-A turning into THC, but cannabidiolic acid into cannabidiol and cannabichromenic acid into cannabichromene, two other important active ingredients. It won't stop in 25 minutes, but the graph shows what happens if you keep going: the THC increasingly degrades into cannabinol.

I then decant into a tin can (not a lined one) frozen into a container of water to cool it down as quickly as possible. The result is a pale green solid with a pleasant scent and a very smooth onset. Seems to have a nicer effect than butter extractions, and certainly neater and more versatile. The whole process takes about two hours; most of that is heating up the oil and stabilizing the temperature. One of these days I'll invest in a metal hot plate/stirrer combo; they're less than $200 and afford precise temperature control.