SA indoor noob needs help choosing COBs

- Thread starter Mazoz

- Start date

Mazoz

Well-Known Member

I

That's why I enquired about shipping charges on cobs. the shipping charges (32 Dollars) eats up the saving he offers in terms of purchase price. Unfortunately Cobkits doesn't control the couriers price (although I wish he did lol) and this is not within his control.

With Digikeys if I break the 2000 rand mark they do free shipping which is a saving. Will then have to worry about tax rate only.

Now that i understand LEDS a bit better I am going to look at the strips you spoke off and boards another poster mentioned. I bet they will be cheaper then the COBS. However I have never soldered a damn thing in my life so that's why the COBS interest me. They seem simpler to do.

I have bru.Have you even looked at cobkits, he tends to be cheaper?

That's why I enquired about shipping charges on cobs. the shipping charges (32 Dollars) eats up the saving he offers in terms of purchase price. Unfortunately Cobkits doesn't control the couriers price (although I wish he did lol) and this is not within his control.

With Digikeys if I break the 2000 rand mark they do free shipping which is a saving. Will then have to worry about tax rate only.

Now that i understand LEDS a bit better I am going to look at the strips you spoke off and boards another poster mentioned. I bet they will be cheaper then the COBS. However I have never soldered a damn thing in my life so that's why the COBS interest me. They seem simpler to do.

Mazoz

Well-Known Member

If you choose the right strips they have little slide in connectors. No soldering required.

Good to know! Lol i will get there. I just wrapped my head around fv and Ohms Law so ill get there. My work has sweet all to do with science so It's like going back to High School (only foggier) I am pretty happy with myself that managed to figure it out. Because I know that driver will work and give me something extra too

mahiluana

Well-Known Member

It`s never recommended to drive a led chip "hard".drive them hard

6 x 40W (34,1V * 1,17A @ rated current) is not enough for your size (1,3x0,9m)

you should buy 10pcs. of those <<Bridgelux BXRC-40E >> to receive 400W @ 148lm/w.

Driving this chip @ 1,17A you need a good(expensive) heatsink with active cooling (fans).

Otherwise i doubt, that your lamp build will have longlife.

So buying 10cobs (115,- US$) + act.heatsink can cost you easiely 250,-US$

and you will always spend additional extra electricity with the fans.

with 10 x 200w chip boards (85,-US$) you won`t need heatsinks,

if you drive them @ 20% of rated current.

and even going tu buy 20 x 200W @ 10% current gives you ~160lm/w and much better spread over a sog /scrog for a lower price.

if you look for the cheapest prices to buy diy components - china is obviously the most atractive and international marketplace and not all products are crapy shit... if you know how to take advantage out of prices, lumens output and heat management.

The same board used in a 200W-floodlight @ max. current is one of these crapy chinise products, because the aluminium cases and boards of these floodlights reach up to 100°C with a bad, cheap, pasive heat management .

To give you a final idea i would go with 2 x elg240 c1750a and 20 x 200w boards(10warmw.+10coolw.)

and wire each board to a Vf (4 x ~35V) = ~140VDC @ 175mA and drive 10 boards in parallel/driver.

with one driver of warmw. and the other in coolw. you could fade between warm/ neutral/ coolw. and // 200W <---> 500W //

<- 130cm ->

0 - o - 0 - o - 0

o - 0 - o - 0 - o

0 - o - 0 - o - 0

o - 0 - o - 0 - o

this cost !me: 2driver100$ 20pcb166$ south africa may be a bit more expensive.

: with only 10 pcb and less efficiency the total price is 183,-$ + wires & wagos. (+duty?)

Good luck with the new government

mahiluana

Well-Known Member

without soldering iron in the DIY section - you stay virgin and get lost baby - just do it for the first time ! it`s easyHowever I have never soldered a damn thing in my life so that's why the COBS interest me. They seem simpler to do.

without burnings or breathing bad stuff into your lungs

Mazoz

Well-Known Member

Wow thanks for taking the time to write that .It is appreciated. Actually thanks for even bothering to read haven't got many responses as hoped. Be that as it may....It`s never recommended to drive a led chip "hard".

6 x 40W (34,1V * 1,17A @ rated current) is not enough for your size (1,3x0,9m)

you should buy 10pcs. of those <<Bridgelux BXRC-40E >> to receive 400W @ 148lm/w.

Driving this chip @ 1,17A you need a good(expensive) heatsink with active cooling (fans).

Otherwise i doubt, that your lamp build will have longlife.

So buying 10cobs (115,- US$) + act.heatsink can cost you easiely 250,-US$

and you will always spend additional extra electricity with the fans.

with 10 x 200w chip boards (85,-US$) you won`t need heatsinks,

if you drive them @ 20% of rated current.

and even going tu buy 20 x 200W @ 10% current gives you ~160lm/w and much better spread over a sog /scrog for a lower price.

if you look for the cheapest prices to buy diy components - china is obviously the most atractive and international marketplace and not all products are crapy shit... if you know how to take advantage out of prices, lumens output and heat management.

The same board used in a 200W-floodlight @ max. current is one of these crapy chinise products, because the aluminium cases and boards of these floodlights reach up to 100°C with a bad, cheap, pasive heat management .

To give you a final idea i would go with 2 x elg240 c1750a and 20 x 200w boards(10warmw.+10coolw.)

and wire each board to a Vf (4 x ~35V) = ~140VDC @ 175mA and drive 10 boards in parallel/driver.

with one driver of warmw. and the other in coolw. you could fade between warm/ neutral/ coolw. and // 200W <---> 500W //

<- 130cm ->

0 - o - 0 - o - 0

o - 0 - o - 0 - o

0 - o - 0 - o - 0

o - 0 - o - 0 - o

this cost !me: 2driver100$ 20pcb166$ south africa may be a bit more expensive.

: with only 10 pcb and less efficiency the total price is 183,-$ + wires & wagos. (+duty?)

Good luck with the new government

I like your proposal. It is certainly more efficient.

I must apologize because I forgot to mention that I already have a 400 watt cool hood magnetic MH /HPS light which I picked up for R 400 or 35$ brand new 2nd hand (lol dude still had them in the box and is a trusted friend) .I just need a globe which will set me back approx R200 to R300 ( 26 $). The problem is that deal was a one off and I haven't found anything like that again. The LED DIY is to supplement as the 400 HID isn't enough on its own.

I am hesitant to wire in parallel in the growmau5 basic video I watched he spoke of run away current and that shit scares me. If I do it in series only I assume I will need a better driver then you suggest...the 200v cobs that would also be more expensive I reckon. I am going to write down your suggestion and cost it out on digikey that will help me decide

Will google the Chinese suppliers lol.

I was reading a thread in a grow with cheap chinese cobs diys a pity it was abandoned I think you commebted there

mahiluana

Well-Known Member

that problem can only ocure if your heatmanagement is insufficient and your chips run @ high current rates. if you drive a chip or a board @ ~ 10-20% of rated current,run away current and that shit scares me.

that "runaway"will not happen and with a board surface of 26cm x 13cm never ever.

i sell these boards here in Germany - but a letter to SA with up to 2 kg should be no problemWill google the Chinese suppliers lol

< 7 boards / 1kg ~ EUR 10,-

< 15 boards / 2kg ~ 20,- for shipping as certified letter

outside EU i can offer prices without vat

- and if you want duty free i declare as low as you want. Just ask if you want an offer.

CobKits

Well-Known Member

i can ship for as little as $12 but its uninsurable and they often get lost so im not a fan of that for obvious reasons. i usually only do that when people are buying $20 or less of holders etcThat's why I enquired about shipping charges on cobs. the shipping charges (32 Dollars) eats up the saving he offers in terms of purchase price. Unfortunately Cobkits doesn't control the couriers price (although I wish he did lol) and this is not within his control.

Mazoz

Well-Known Member

Agreed and the number of cobs that i want to buy from you are in excess of that minimum order amount.i can ship for as little as $12 but its uninsurable and they often get lost so im not a fan of that for obvious reasons. i usually only do that when people are buying $20 or less of holders etc

So i will be stuck with internationals

ANC

Well-Known Member

I don't think so, max Tc is something like 95Ctherwise i doubt, that your lamp build will have longlife

mahiluana

Well-Known Member

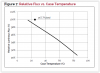

what do you expect in a curve between temps. / luminous flux / and longlife ???max Tc is something like 95C

95°C is close to death - like 42°C fever - or 5°C more in global warm up.

i run my chips @ 20°C in the morning and 40°C in the evening.

mahiluana

Well-Known Member

to specify performance ? i would simply say:to specify performance

the lower the chip temp - the higher is flux and longlife !

and to drive a 50W quality chip @ Tc > 65°C without a good heatmanagement is just stupid.

mahiluana

Well-Known Member

i don`t get it in my head, ...that it is so hard, ...for soo many people, ...to understand:Which part of this don't you get?

- that heat is a main issue of led-tec.

- that watercooling is the solution and 3 times more efficient, than any air - or pasive cooling,

- because heat efficacy of a led chip is ~ 75% and led light efficacy only ~25%.

- and many people still believe it`s vice versa or just ignore their own knowledge

- and then spending hours and weeks on discussions about efficiency of little green or red dicks...

...in the action center called rius kindergarten .

mahiluana

Well-Known Member

3 ways - a watercooled set up beats the air !!!No Way!

your graph shows only 1 reason why a low Tj can rise efficacy of led light. (~10%)

- the 2nd reason is much more evident and important.

Light-Heat-Cogeneration

is a simple addition of light & heat efficiencies.

While your light efficacy = your energy efficacy

My energy efficacy is light + heat !!

I`m able to rewin 60% of the electr. input as stored, hot service water to use it in my household.

That means i.e. a 1000W coolmac system with a daily consume of 15KWh can produce 9KWh of stored heat power = (~250L of hot service water)

This is only ~80% of the total produced heat - and the radiated heat by the LES is still ~20%. (and hard to rewin), but also desired to heat your grow room.

You can be shure that all heat measuring with hot water are ways more exact than a measuring of radiant flux in an integrating sphere.

If your chip is 25-30% light efficient @ Tc 90°C - it will rise to 27,5-33% @ 15°C.

With an aircooled led i can not reach this region without an expensive amount of heatsinks and driving dozens of fans, while my watercooled chips has no heat resistance at all

- and Tc = ~Tj = watertemp. (15-35°C)

and this is the third way, that rise efficiency of a watercooled lamp build.

you have to spent much more additional electricity for active cooling (10-20 fans // 25-50w)

- i spent 2,4w with a tiny waterpump able to cool down the whole 1000w much lower, better smarter.

what do you want, if you go out to buy a car ???

Yes - it must be a good one ---

...and they are all watercooled

...and they are all watercooled

ANC

Well-Known Member

Take pictures of the hot water tank side of things.... I am having problems visualising how you would tie it into a house's hot water system without big expense.

It is so hot here this time of year, we don't even switch the hot water on (plus we have massive water rationing). But it might be interesting in winter.

PS, just dropping the sinks to 15 degrees may win you 7% in lumens max. I'd be more interested in the free hot water.

Not a drop of water in my beetle's engine. it does fine with air cooling.and they are all watercooled

It is so hot here this time of year, we don't even switch the hot water on (plus we have massive water rationing). But it might be interesting in winter.

PS, just dropping the sinks to 15 degrees may win you 7% in lumens max. I'd be more interested in the free hot water.

Last edited: