Hot Diggity Sog

Well-Known Member

I'm going to be making some alterations during this run...something I was hoping to avoid.By itself very acceptable temps but I do run a little lower with chiller. Specifically 65, but it climbs up to 69 before the chiller kicks in. Point is if you want to drop it one or two degrees you can. Colder solution does allow for slightly increased DO.

The air stones are already sort of extra. The flow is constantly aerated along the path too plus you got the venturi. If the air stones, or lack of, would be the problem, then theoretically the plants at the end of the line should be more affected than at the start. With multiple strains that can be misleading though, the one at the end could be the one that deals best with it.

I noticed some of that curling I think you are referring to, I got that a little sometimes before they take off, once they are able to transpire enough and fast enough it always disappeared.

Also, you mentioned you couldn't lift the pots from most plants to check the roots. While that is obviously inconvenient now it's by itself a good sign. If the roots gone bad and you lift a pot it won't resists as much (and break off its roots so be careful). Just something I considered doing myself before I figured I can take pics of my roots through the holes of my sprayers, melt a peeping hole in a tube near on of the worst plants, so you can check the roots.

They are probably done creating most of the root mass by now, is it possible the shallowness of the flow is causing issues now? Can you see if it raised slightly because of the roots?

I'm not very satisfied with the rate of water flow. If I pull a net pot up high enough to see the water, it looks almost stagnant.

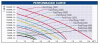

I swapped out my 396 gpm feed pump with one almost twice its size and saw no improvement in the rate. When I first set this stuff up I made a bone-headed decision. The water pump pumps from the rez, thru the chiller and then into the tubes. The chiller might be limiting the flow. I'm going to redesign this aspect 1st so a pump moves water from the rez, thru the chiller and back into the rez. Have a separate pump that moves water from the rez to the tubes. I'll try both pump sizes and see if flow is affected. If it is not, then it's gotta be the 1/2" hose that is the limiting factor...too small. In this case, I will have to drill another and equip it with another fitting and run 2 feed pumps to the tubes. Running 2 feeds is part of my new design anyway so this will be a good proof of concept. Better flow and even more importantly, if a pump dies I'm not fucked.